Skin friendly materials

We’re passionate of innovation. For us, any technical solution isn’t good enough. We’re still looking for new opportunities. Our products are made of high quality fabrics with unique construction and perfect functionality. While designing, our constructors and engineers think about future. Innovation and technology are built-in our DNA.

ActiveDistance™ is an technical off-loading lamination with 3-layered construction. It’s made of EVA foam double-sided laminated with non-elastic polyamide layer that is easy to attach. This self-gripping function of ActiveDistance™ provides wide range of adjustment and perfect fitting. What is important, ActiveDistance™ is non-elastic fabric so it stabilizes your body in a perfect way. Thanks to using the comfort foam, the device is really soft what influences on the comfort of using it. Waterproof material.

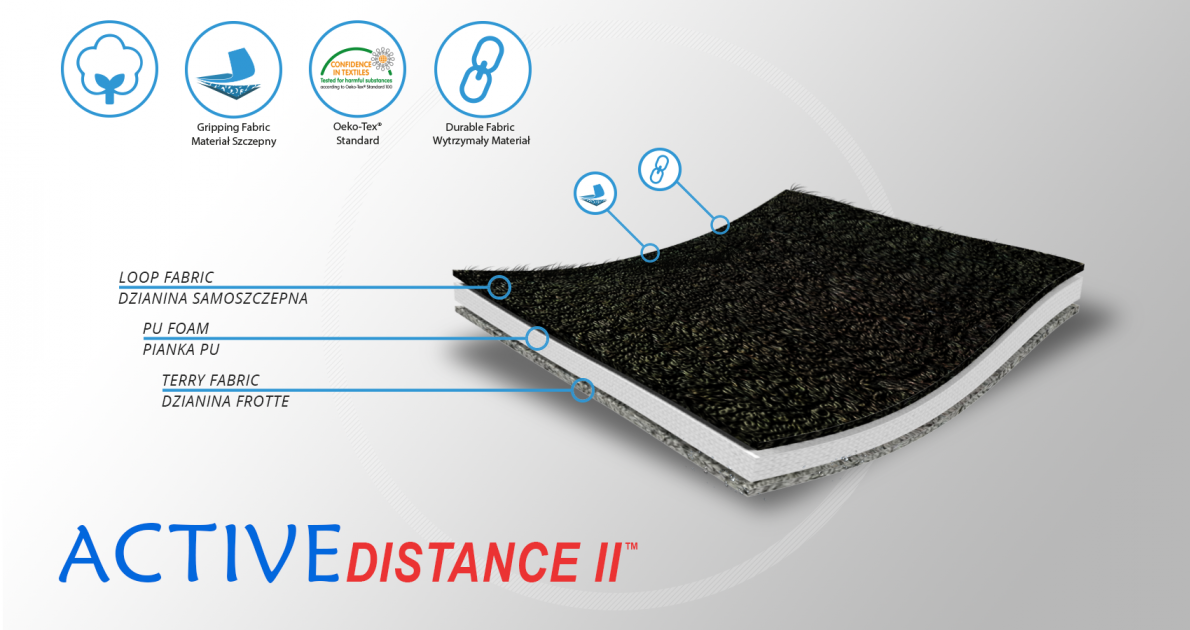

ActiveDistance II™ is an active 3-layered fabric made of non-elastic polyamide self-gripping layer, comfort foam and cotton terry. The last one layer is responsible for maintaining your skin dry. This material is skin-friendly and has the Oeko-Tex Standard 100 certificate. Self-gripping function of ActiveDistance II™ allows to fit the braces precisely.

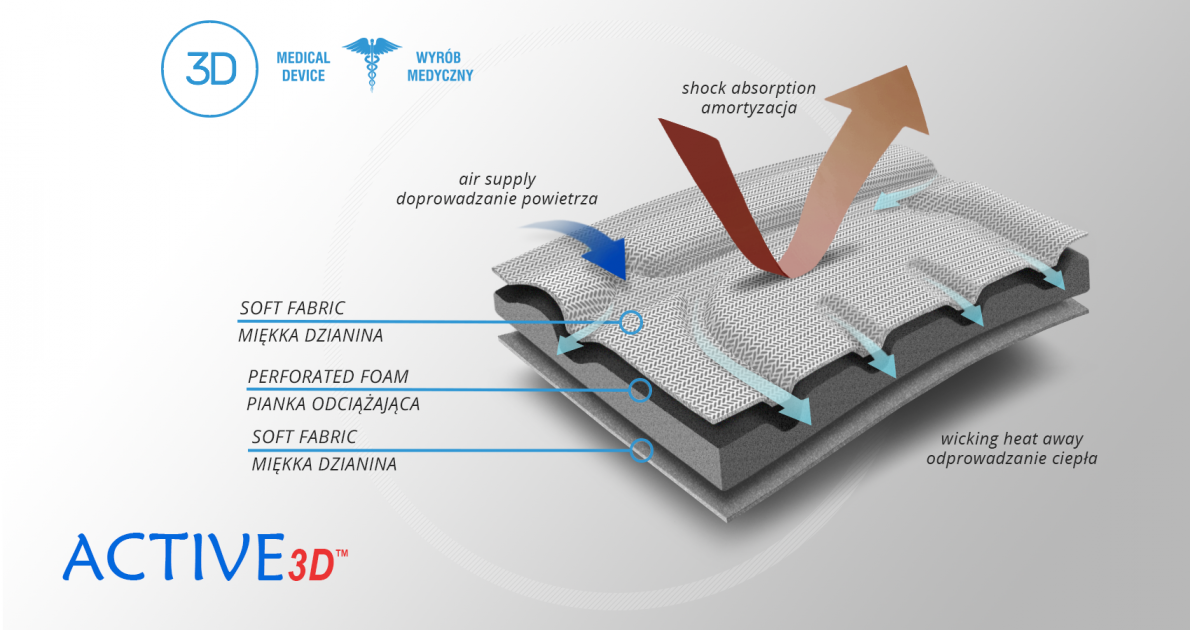

Active3D™ is thermoformed fabric made of special foamed, cell-closed designed material. It reduces the pressure on the body or any abrasions made by orthopaedic stays and aluminum splints. It is fully waterproof fabric and does not absorb sweat. It’s easy to clean. Due to its features, the fabric is an excellent product for making medical orthopaedic braces and orthoses. ACTIVE 3D™ has various external self-gripping layers. Our material has special, thermoformed properties and may be shaped according to the functional goals of the final braces.

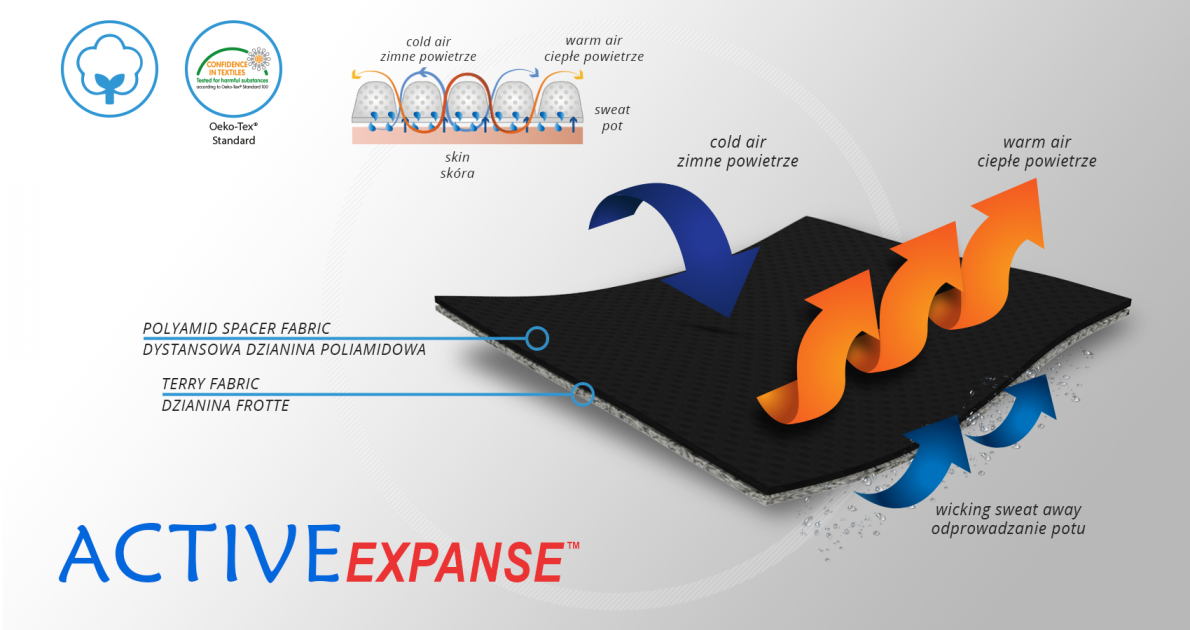

ActiveExpanse™ is an innovative, active 3D lamination with high air permeability. This spacer material is light made of 2 parts: external polyamide durable 3D layer and skin-friendly cotton layer with Oeko-Tex Standard 100 certificate. ActivExpanse™ is not elastic what improves stabilization. External 3D spacer layer is hypoallergenic and provides high air permeability and minimal water and moisture absorption. Our medical devices made of this fabric are very comfortable.

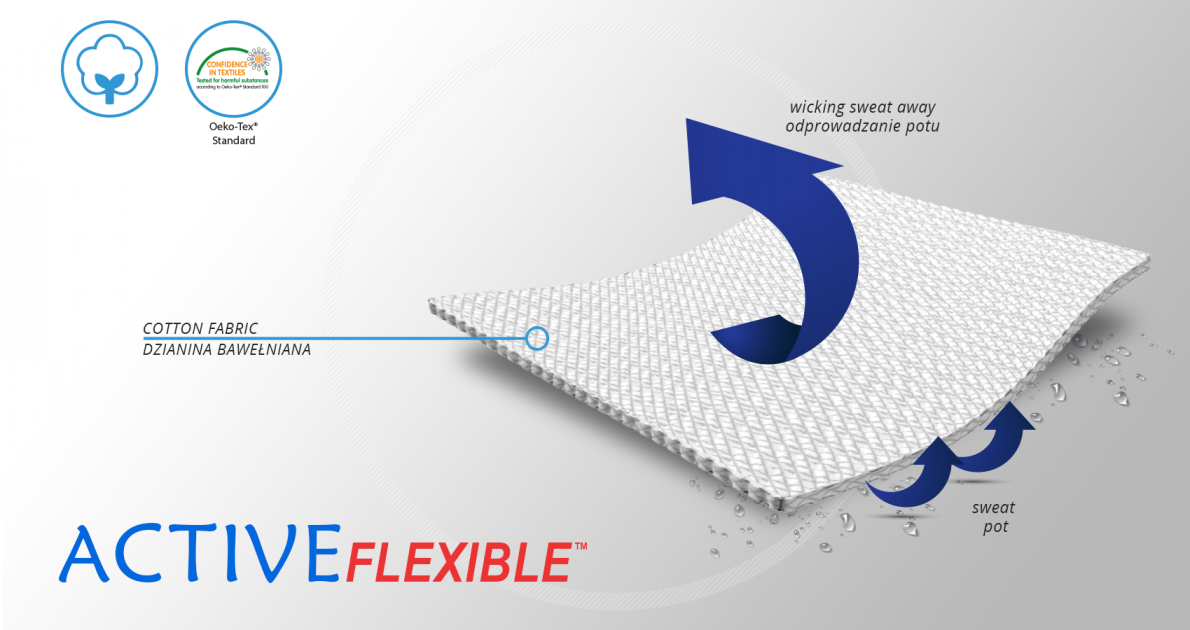

ActiveFlexible™ is a unique, ecological rubber, made of knitting machines. It’s cotton material without seams what prevents against the skin injuries. ActivFlexible™ can be stretched in all dimensions providing perfectly fitting. Between the braids air flows freely and skin can breathe. In addition in high compression, these rubber braids provide a gentle massage for skin. ActiveFlexible™ is very friendly for skin.

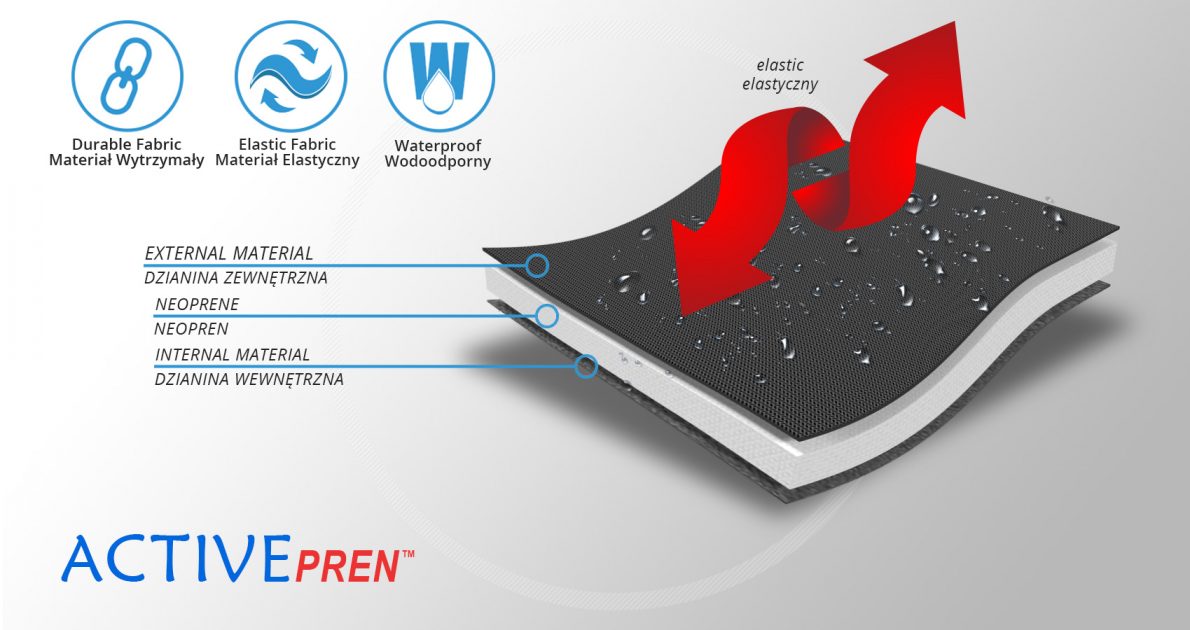

ActivePren™ is an active three-layer material consisting of two elastic jersey cover fabrics and a core made of neoprene foam. This material is characterized by softness and high flexibility. A very important advantage of this material is the fact that it is not a knitted product, it does not have thick fibers, so that the weaves of the material do not imprint on the patient's skin and do not cause abrasionsin places of high compression. Products made of ActivePren are the strongest and most effective stabilizing orthoses available on the market.

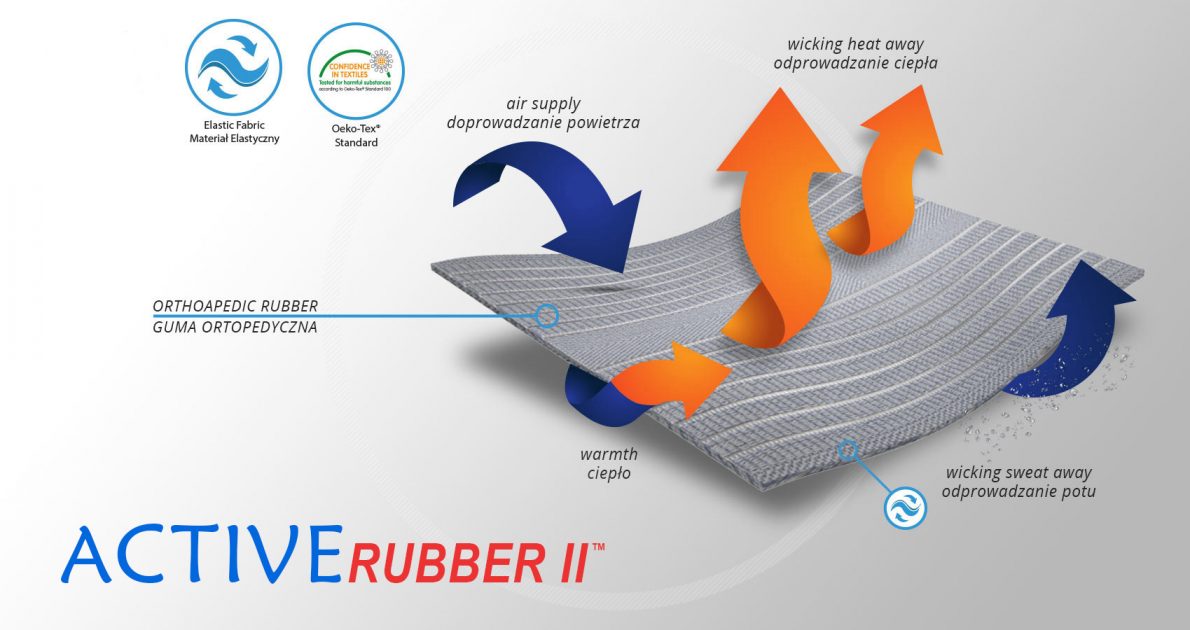

ActiveRubber II™ is strong and bidirectional elasticity. It can be stretched, increasing the length and width, what improves compression. Between the braids air flows freely and skin can breathe. In addition in high compression, these rubber braids provide a gentle massage for skin. Our orthopedic rubber is very friendly for skin.

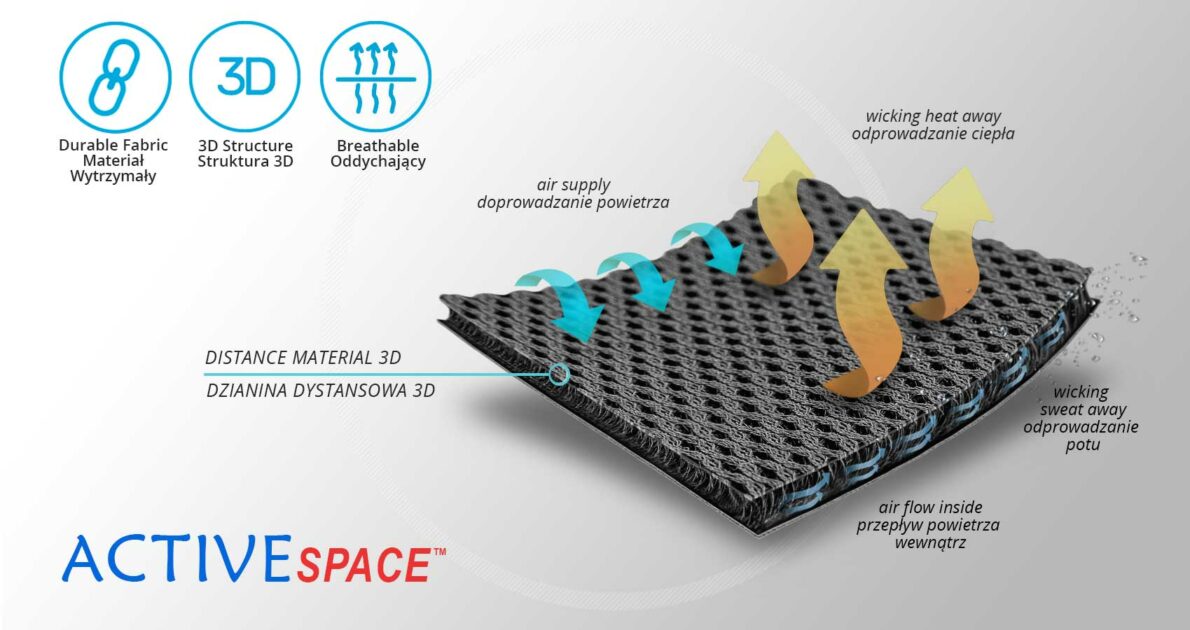

ActiveSpace™ is a spacer, polyamide 3D lamination with high skin ventilation. It is very lightweight, consisted of 2 layers. Between them, we use polyamide braids. ActiveSpace™ is not elastic what improves stabilization. Inside the lamination, between 2 layers, the air flows freely, maintaining minimal water and moisture absorption. Waterproof material.

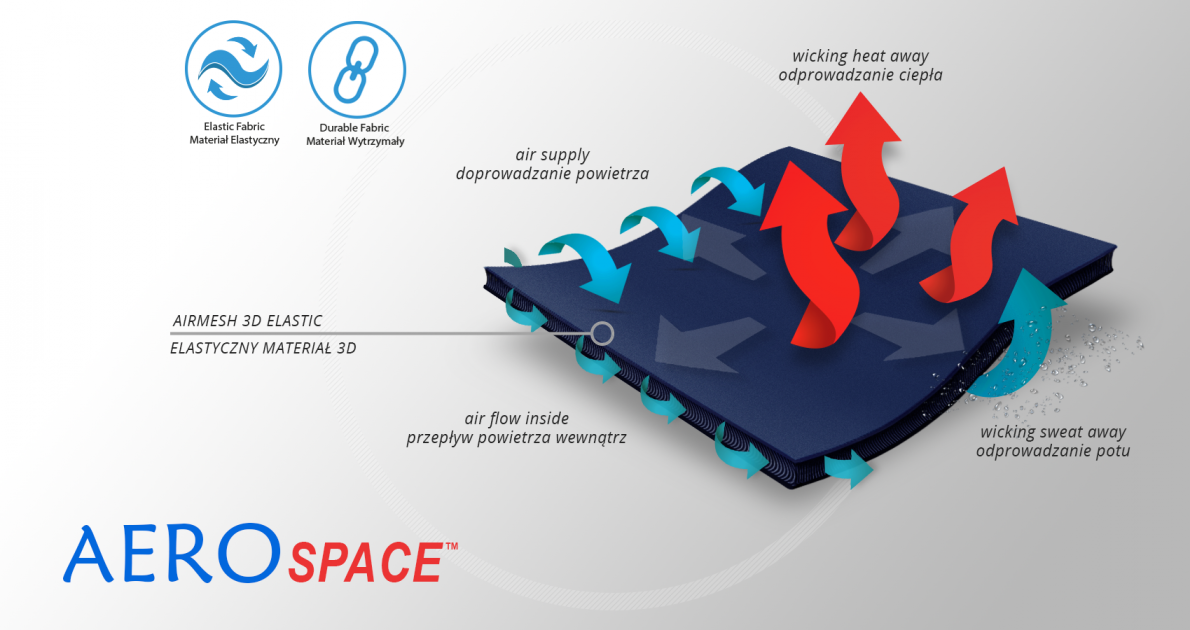

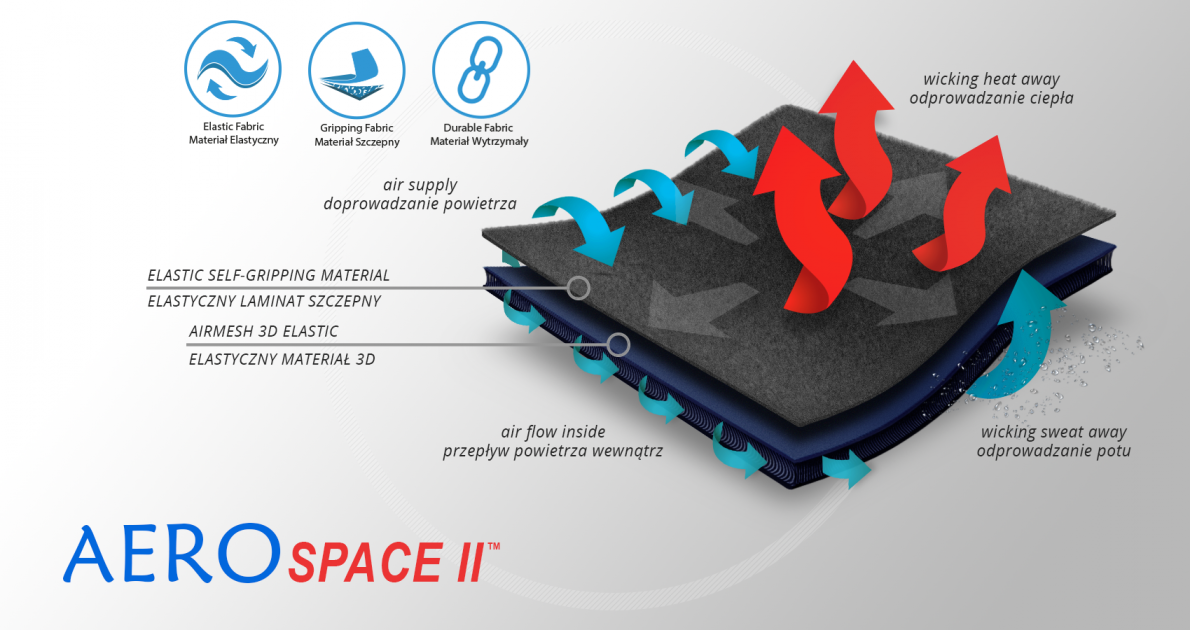

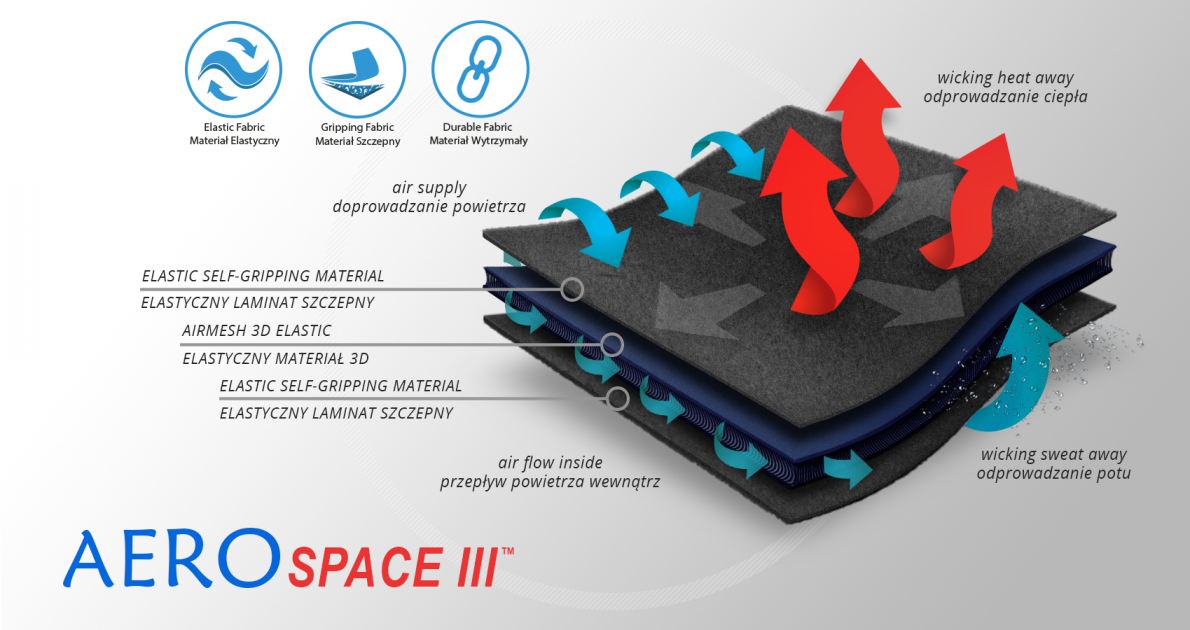

AeroSpace™ is an innovative new generation raw material. It is a distance elastic 3D knitted fabric consisting of two layers of facings and an interlacing that creates the appropriate thickness of the raw material and has relieving properties. The knitwear is made of the highest quality polyester yarn - guaranteeing high mechanical strength and spandex ensuring its proper flexibility. This material is characterized by a very low weight, high flexibility and a very large openwork structure, allowing for very easy drainage of sweat from the body and bringing fresh air to the skin. Products made of this raw material are neutral to the secured joint, do not heat or cool it, but ensure its proper compression and fit and reduce muscle vibrations generated during physical exertion. Its thickness and 3D structure perfectly relieves the orthopedic splints, stays or other elements mounted on the product and guarantees velvety softness to the touch.

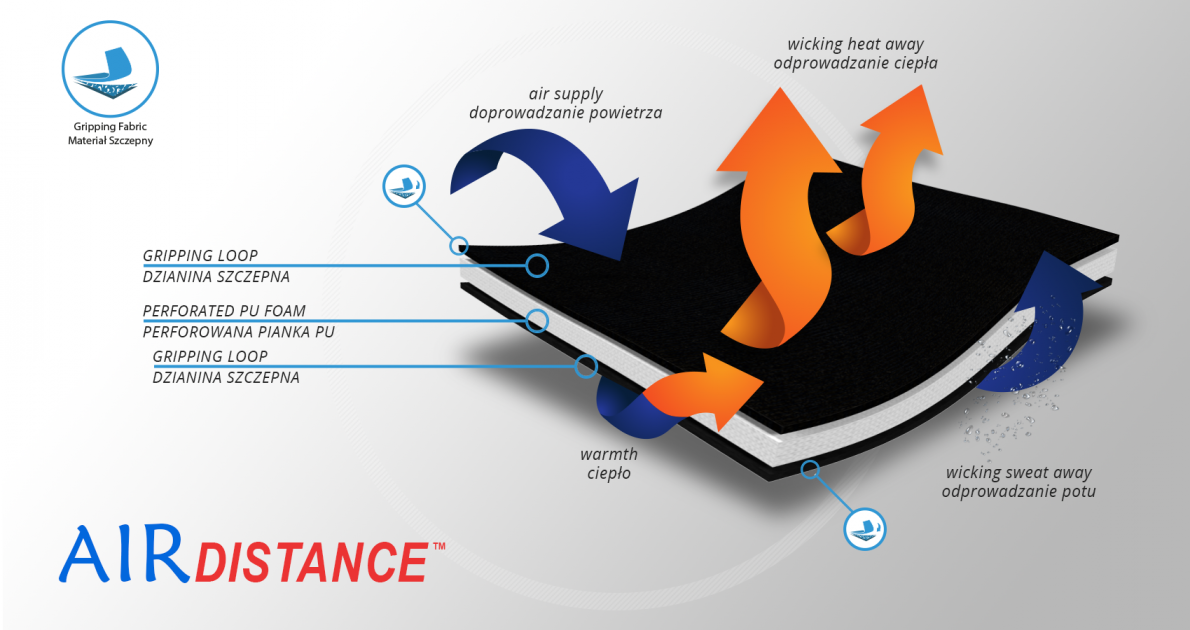

AirDistance™ is an airy 3-layer fabric that consists of perforated comfort foam and 2 durable non-elastic polyamide layers allowing air and water to migrate. This construction makes the skin dry all the time. In addition, the fresh air comes to the skin from outside. AirDistance™ is easy to attach from 2 sides, which allows to fit our braces precisely.

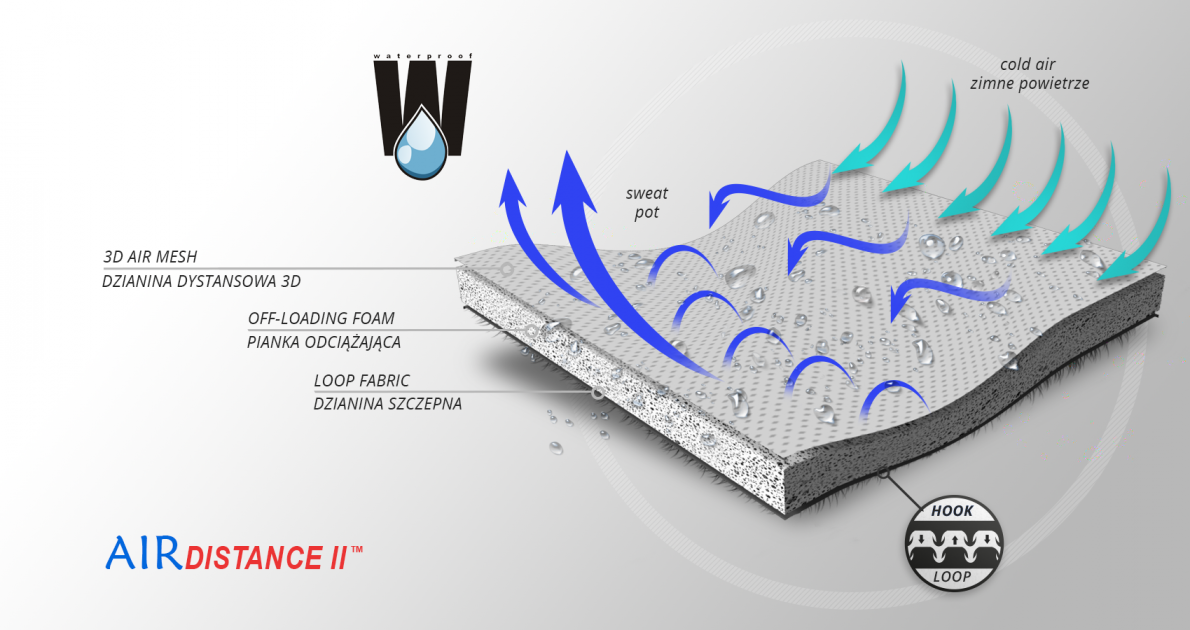

AirDistance II™ is an innovative technological fabric. It’s 3-layered lamination, made of 3 parts: durable and self-gripping and polyamide layer, off-loading EVA foam and polyamide 3D spacer material. The external part is used to attach hard components. EVA foam off-loads these splints and the internal 3D spacer layer provides high air permeability and minimal water and moisture absorption. Waterproof material.

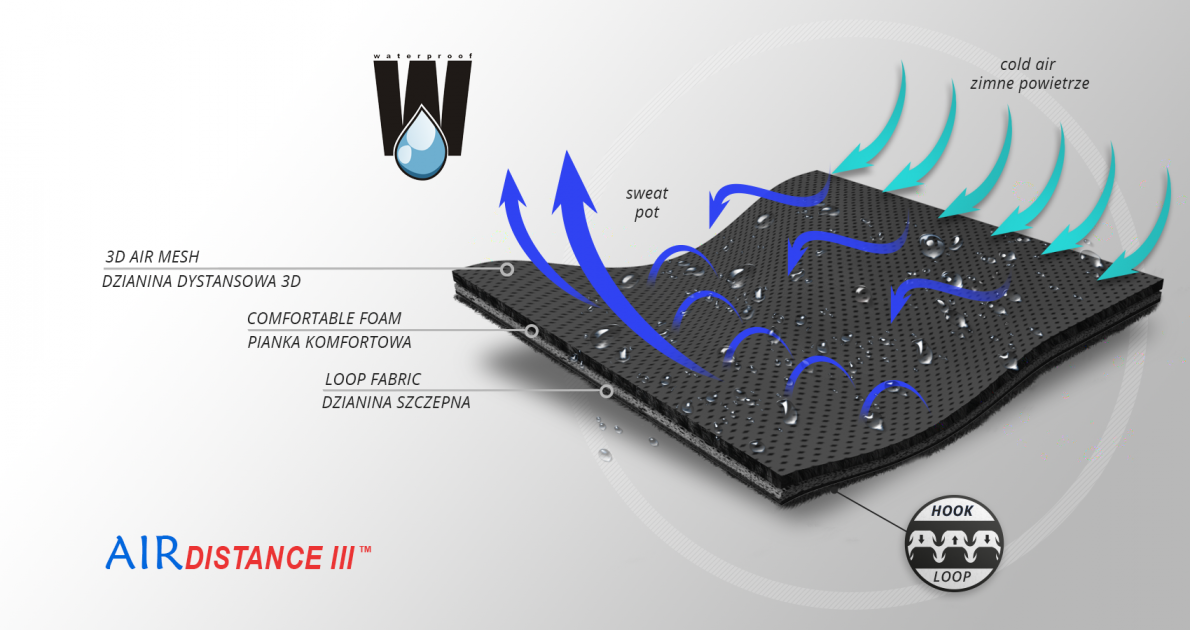

AirDistance III™ is breathable durable lamination. Consists of 3 layers: external self-gripping polyamide, comfort foam inside and internal polyamide 3D fabric. This spacer fabric 3D provides high air permeability and minimal water and moisture absorption. Waterproof material.

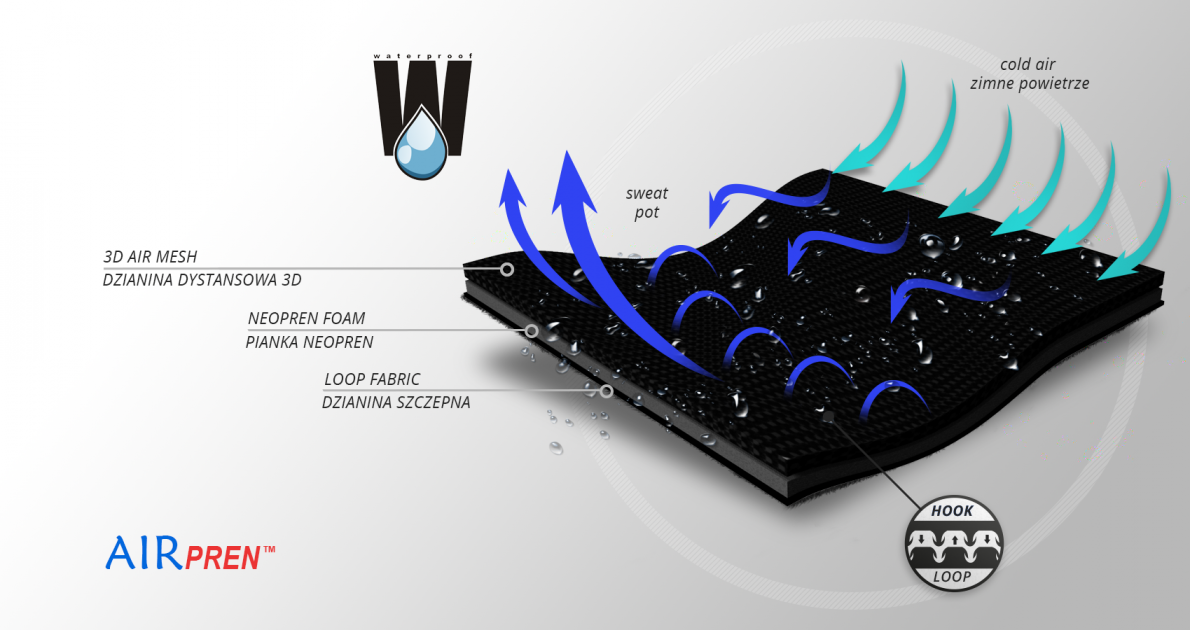

AirPren™ is 3-layered lamination made of: external elastic self-gripping polyamide, neoprene foam inside and elastic polyamide spacer fabric 3D. This lamination is soft and high-elastic. Braces made of AirPren™ are very durable and effective. Internal 3D knitted mesh provides high air permeability and minimal water and moisture absorption. Waterproof material.

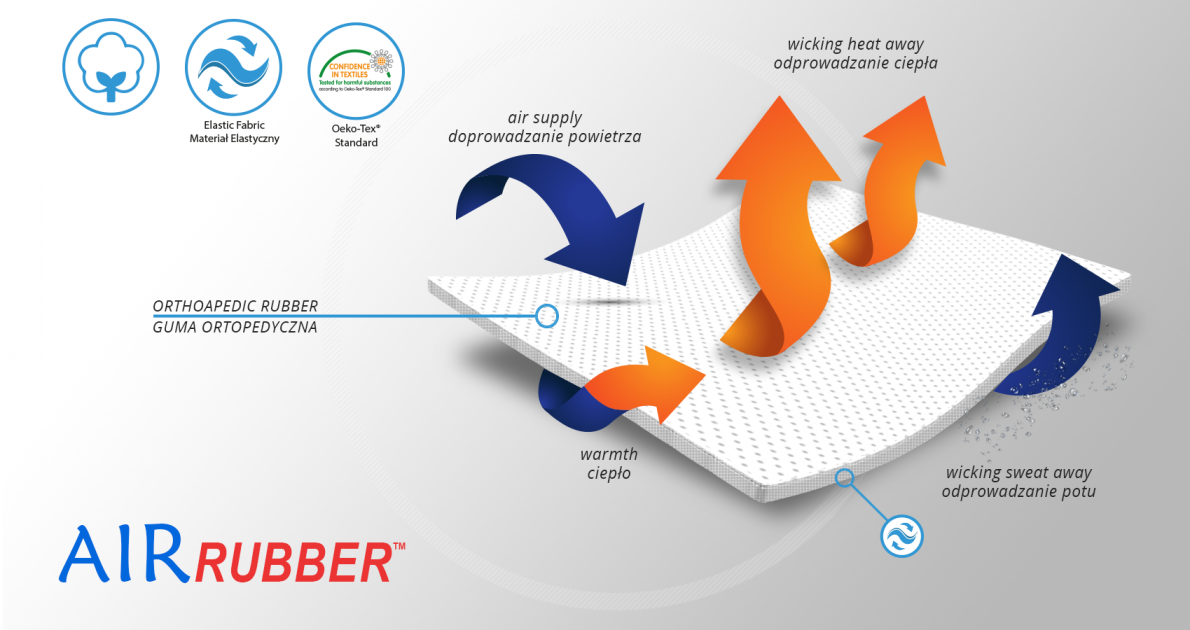

AirRubber™ has unidirectional elasticity and it’s breathable. This lamination is perforated. Between the braids air flows freely and skin can breathe. In addition in high compression, these rubber braids provide a gentle massage for skin. Our orthopedic rubber is very friendly for skin.

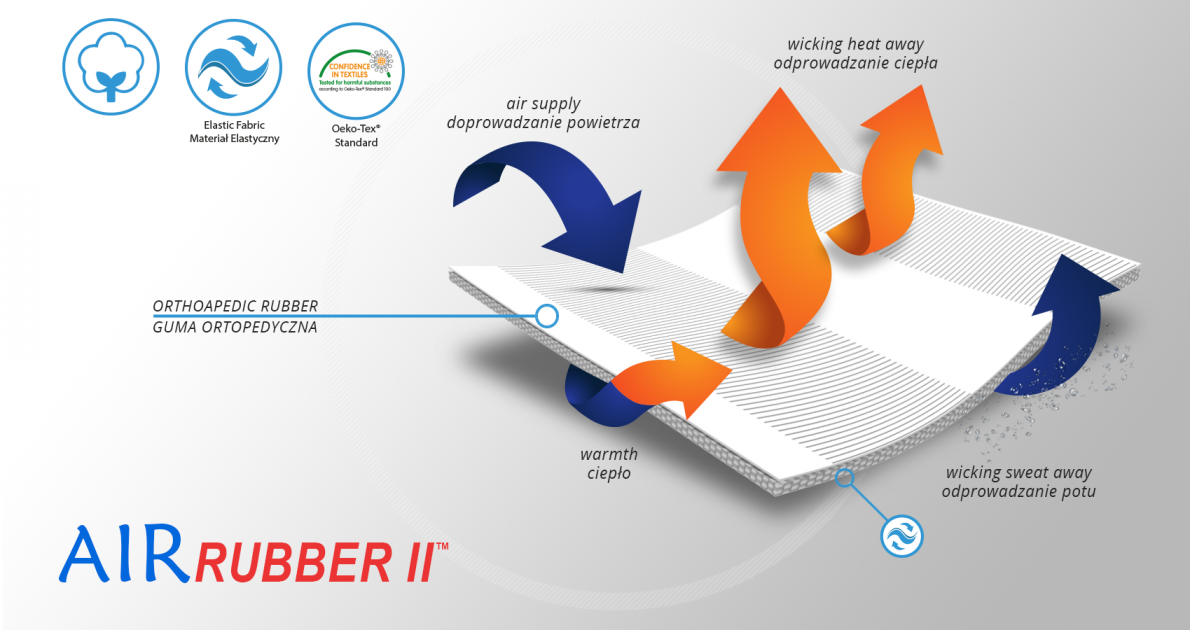

AirRubber II™ is breathable, perforated and has unidirectional elasticity. It can be stretched, increasing the length, not width, what improves compression. Between the braids air flows freely and skin can breathe. In addition in high compression, these rubber braids provide a gentle massage for skin. Our orthopedic rubber is very friendly for skin.

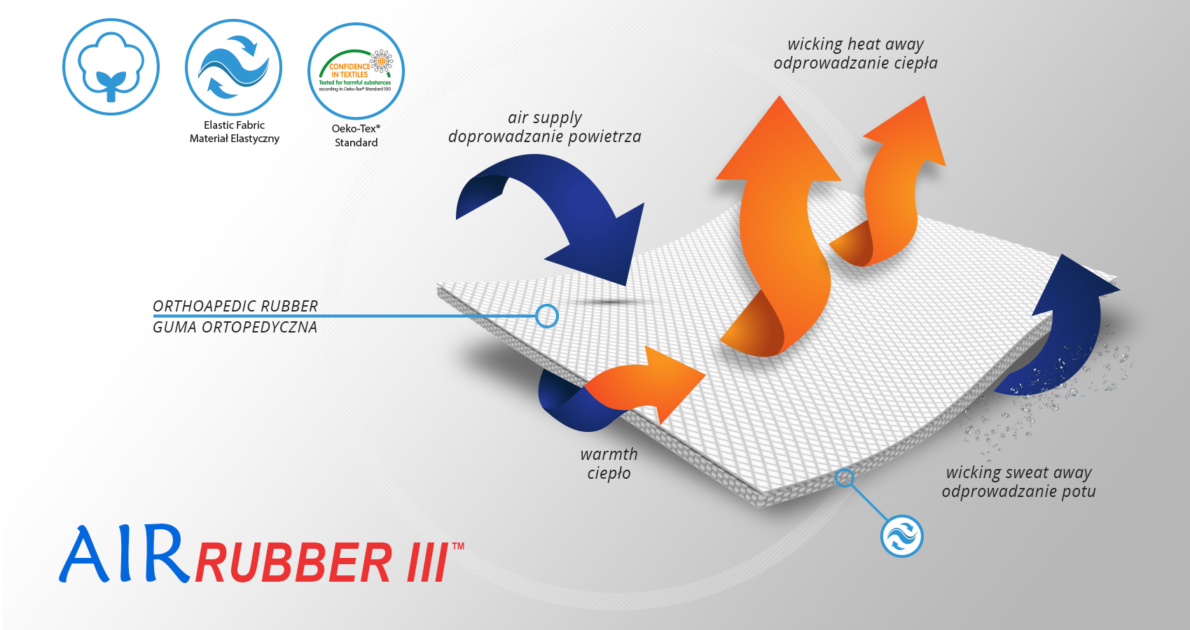

AirRubber III™ has unidirectional elasticity. It can be stretched, increasing the length, not width, what improves compression. Between the braids air flows freely and skin can breathe. In addition in high compression, these rubber braids provide a gentle massage for skin. Our orthopedic rubber is very friendly for skin.

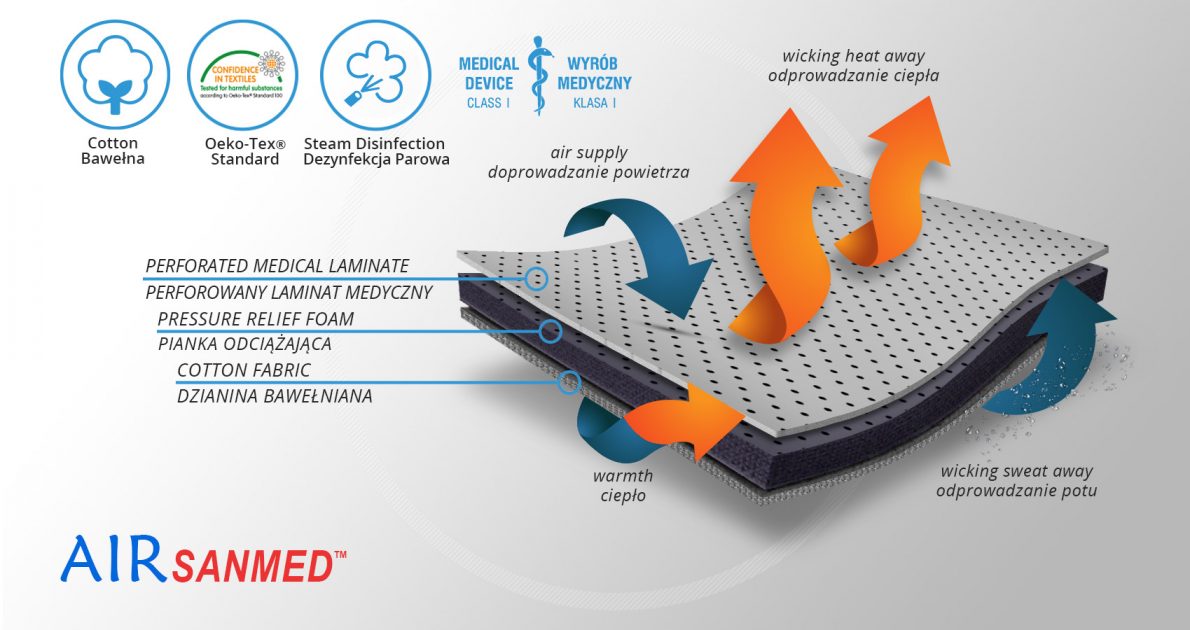

AirSanmed™ isn’t elastic what provides excellent stabilization. The skin has contact with cotton terry with Oeko-Tex Standard 100 certificate. There is semi-rigid perforated foam EVA inside that protect the skin against the metal splints influence. External side of the fabric is perforated medical laminate with antibacterial properties of Silver Zeolite. It provides long-term efficacy and prevents the most dangerous infectious microorganisms such as MRSA and E.coli. AirSanmed™ is in accordance with Health Minister`s ordinance of 3 November 2004 and Council Directive 93/42/EWG of 14 June 1993.

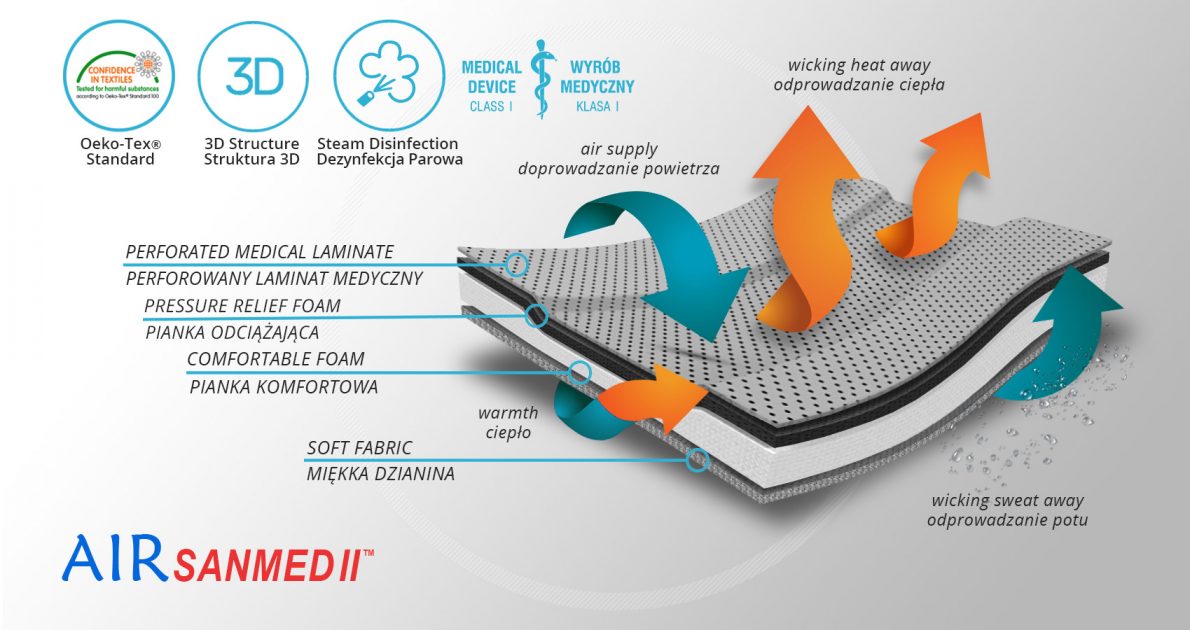

AirSanmed II™ is a multi layered intelligent orthopedic textile which is perfect for orthopedic braces production. It helps to maintain its functionality and high comfort of use. External vapour barrier is washable and possible to chemical or vapour disinfection. It is perforated and laminated with off loading foam. Due to this fact, the fabric is breathable and reduces the pressure of aluminum stays and splints. Off-loading foam is connected with soft, comfort foam improving the comfort of use. It’s laminated with soft, breathable cotton with pH neutral for human’s skin. This knitted cotton is certified with OekoTex Standard100 and fully skin-friendly.

| ALLOWABLE DISINFECTANTS !!! | ||

| Type of active agent or surface-active agent | Maximum content in disinfectant | Spray the surface of the device with disinfectant, leave it for disinfectant’s activation, then wash the device and dry it. |

| 2-propane | 35% | |

| 1-propane | 25% | |

| Ethanol | 10% | |

| Alkyl Dimethyl Benzyl Ammonium Chloride | 0,2% | |

| Glucoprotamine | 25% | |

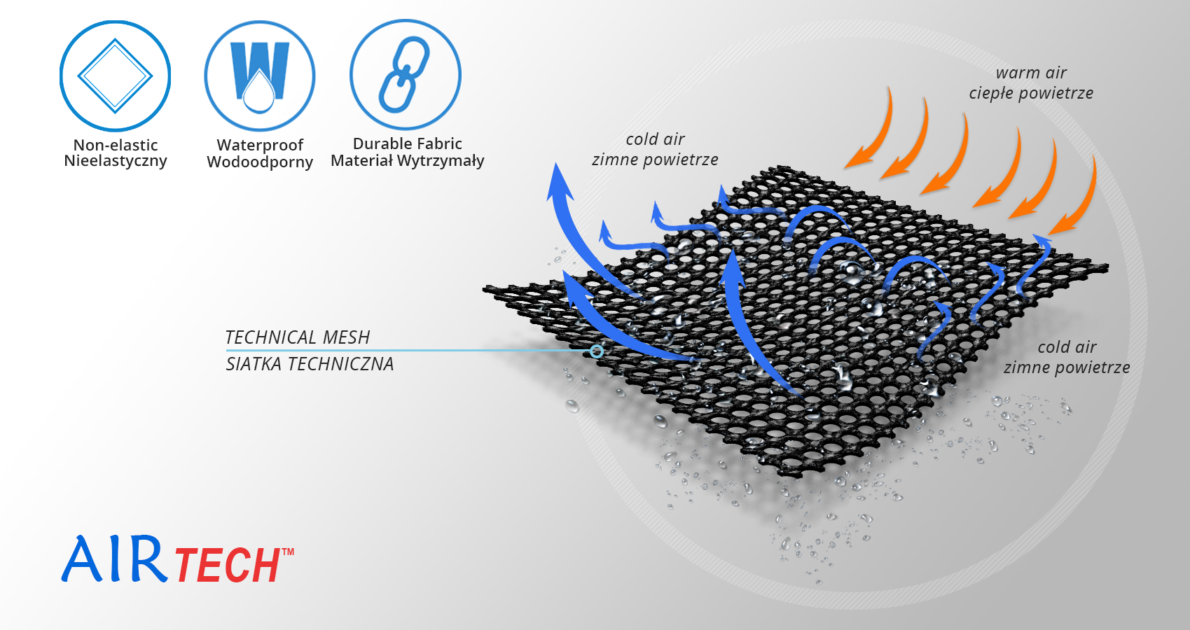

AirTech™ waterproof tech net is created to achieve the most difficult aims and off-loads the high pressures. It’s made of 100% of polyester and its basis weight is 310g/m2 with maintaining only 1mm width. The slim width is resistant to punching even to 120 daN. That’s why, the durability for this material is 95%, what’s unusual in such soft constructions. AirTech™ was tested in Textile Research Institute according to standards: PN-P-04738:1979 i PN-EN ISO 12947-2:2000/AC:2006, where achieved the highest qualities certificates.

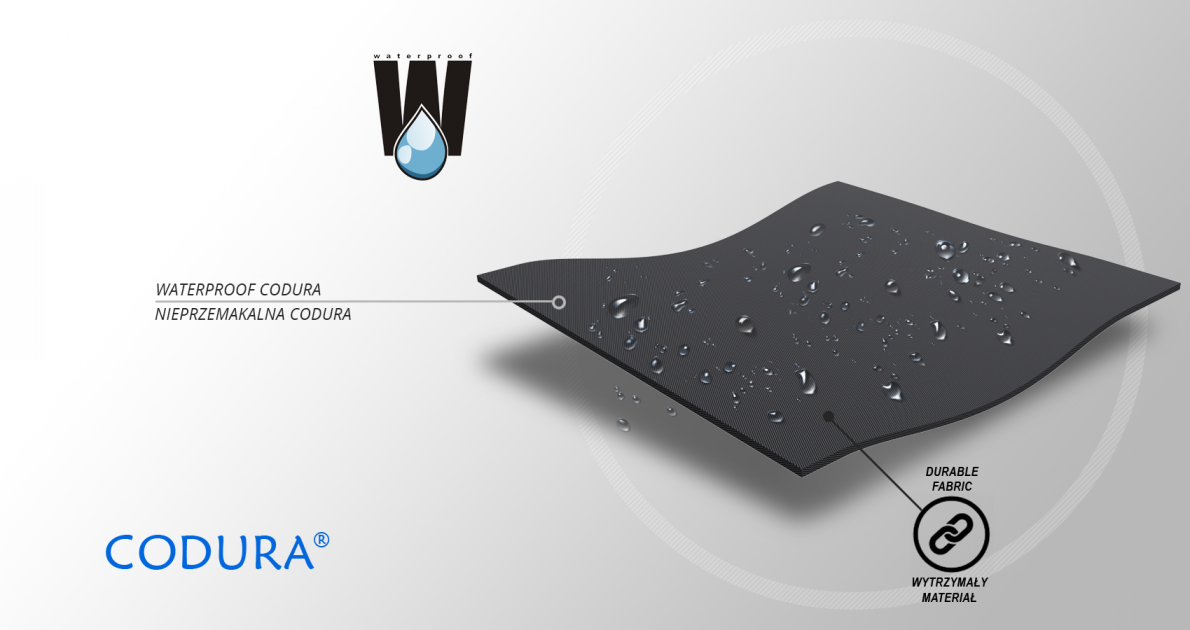

CODURA® is extreme durable lamination made of polyamide with polyurethane layer and Teflon finishing. Structure of fabrics and method of milling make the fabric lightweight but very resistant to damages and extreme conditions. External layer is covered by Teflon. Our devices made of CODURA® are the thinnest and the most durable on the market. Waterproof material.

CottonComfort™ is one of the most comfortable, antiallergic and ecological orthopedic fabric that we use in the production of our products. This raw material consists of a very comfortable polyurethane foam, laminated on one or both sides with a soft and comfortable cotton knit. The knit is made of natural cotton, without any chemicals containing formaldehyde. It is certified by Oeko-Tex® Standard 100, which guarantees safety to the patient's skin. The lamination process takes place without the use of any kinds of glue, but with the use of the flame method, which changes the surface of the polyurethane foam into a sticky surface to which the outer facings of the raw material stick. Thanks to the use of such a production technology, we do not unnecessarily introduce chemical chemicals into the structure of the raw material and we ensure a very high strength of such a connection. CottonComfort™ is used in orthoses in the most delicate places, so as not to cause skin irritation and so that the soft structure of the material tightly fills the free spaces between the orthosis and the patient's body.

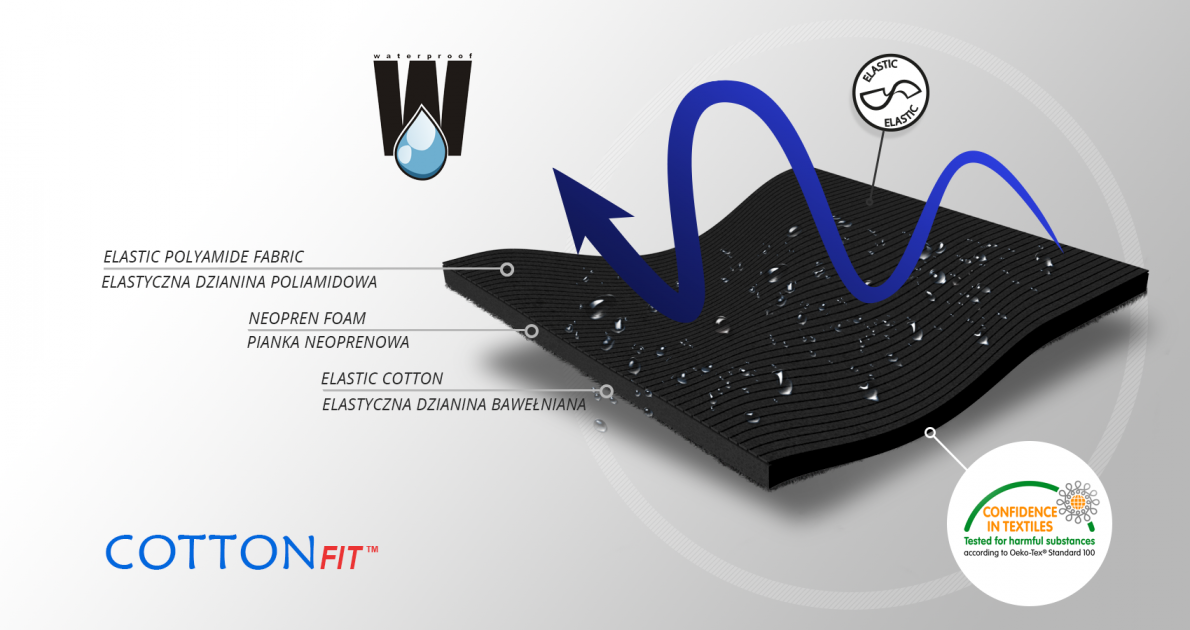

CottonFit™ is an innovative material. It’s 3-layered spacer fabric consisted of elastic spandex, elastic core and cotton layer called CottonPlush. The core’s aim is to improve compression and absorb shocks in joints and muscles during physical activity. The skin has contact with CottonPlush, providing high air permeability and maintaining the skin soft and dry. CottonFit™ has Oeko-Tex Standard 100, what means that it is neural for skin.

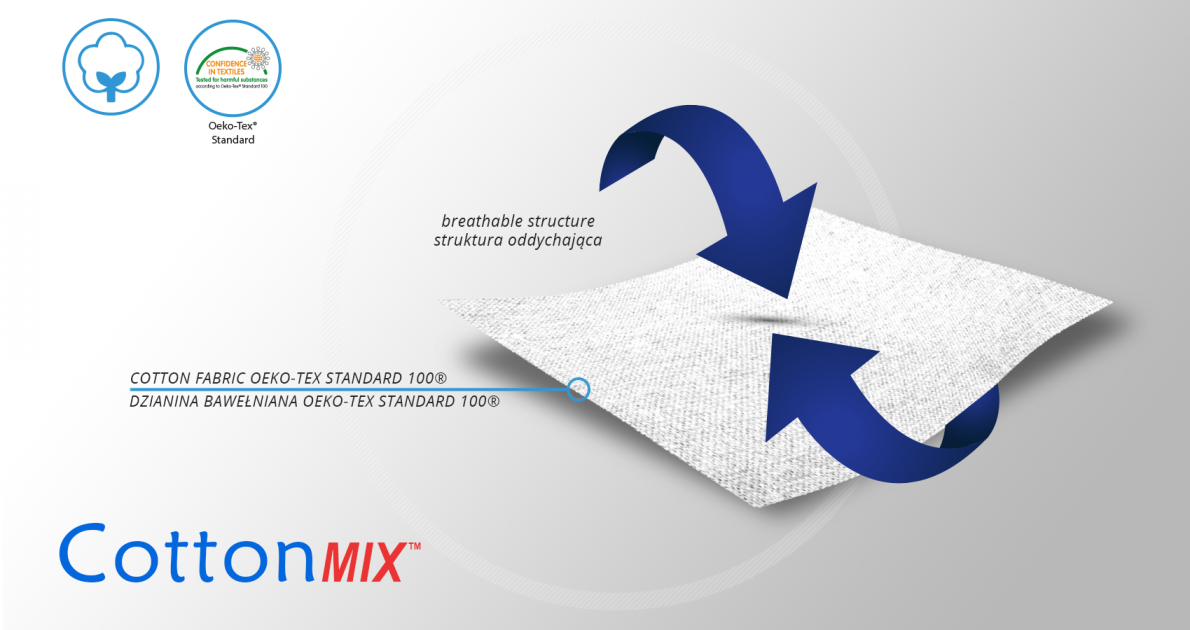

CottonMix™ is an orthopedic, slightly elastic cotton used in our ecological cotton devices. This material is available in different colors and basis weights. All of types of CottonMix™ has Oeko-Tex Standard 100, what means that it is neural for skin.

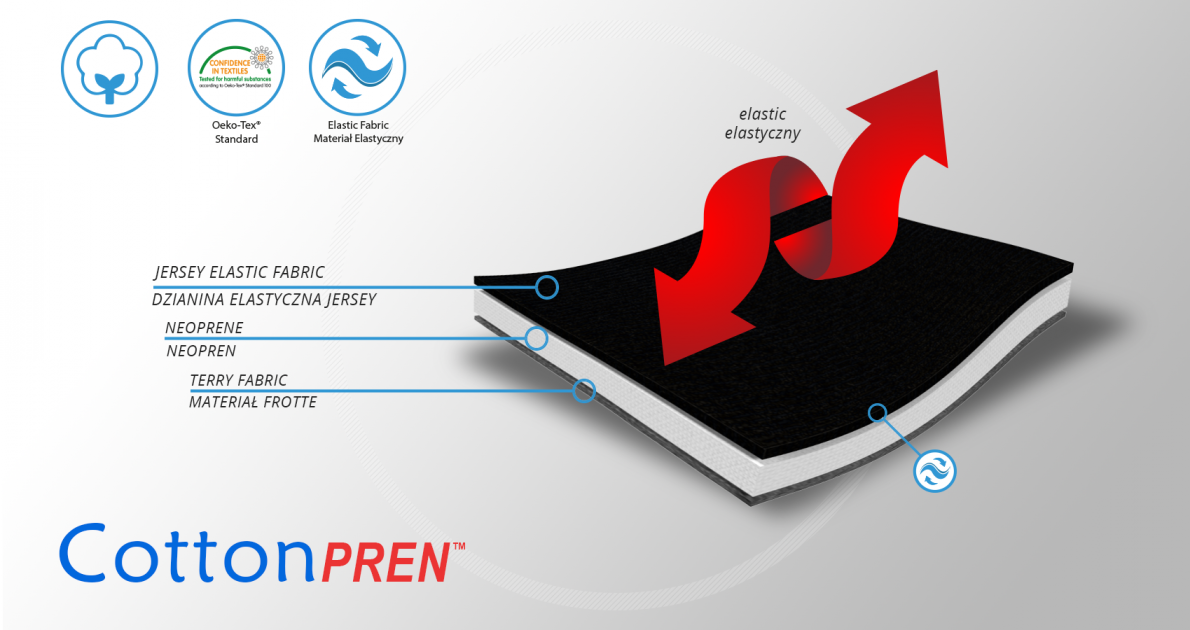

CottonPren™ is innovative and skin-friendly lamination. The devices, made of this material, provide excellent compression, good fitting and absorb shocks in joints and muscles. CottonPren™ is 3-layered spacer fabric consisted of external spandex with neoprene inside. This fabric is made of comfort neoprene foam with polyester lining and internal elastic terry. The skin has contact with CottonPlush, providing high air permeability and maintaining the skin dry. this layer is skin-friendly what Oeko-Tex Standard 100 approved. It’s soft and elastic what improves the compression. The fabric is very durable and can be washed time and time again without any loss of the elasticity. It makes your skin dry and it’s environment-friendly, because doesn’t contain chlorine.

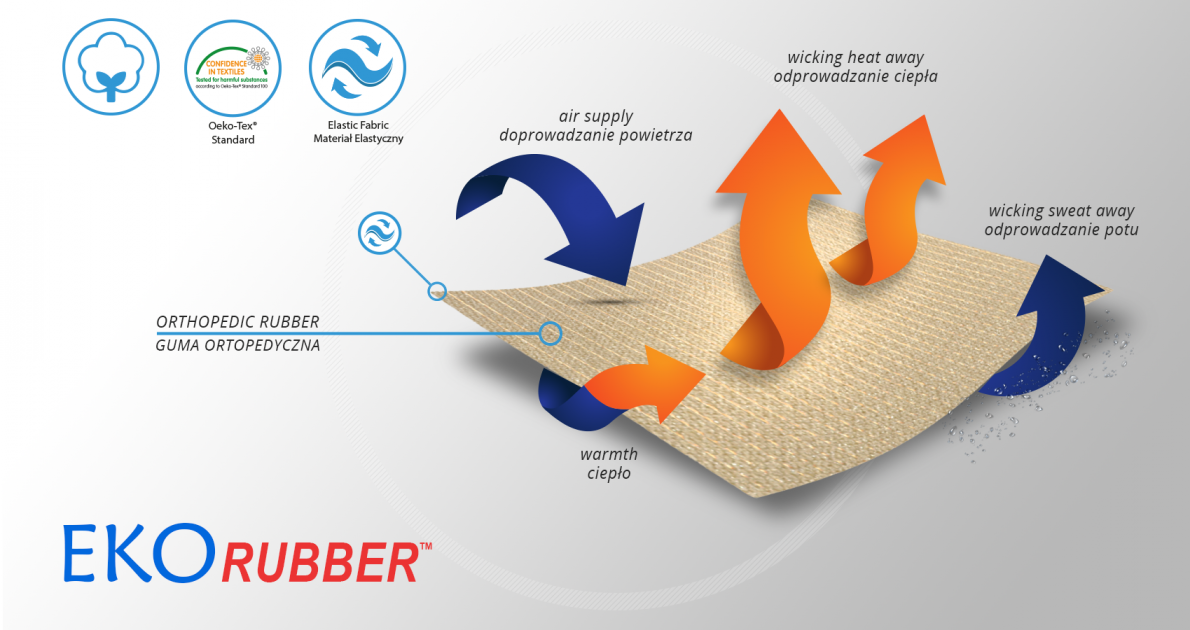

EkoRubber™ is ecological, cotton, firm and soft orthopedic rubber with high elasticity. It can be stretched easy and fit precisely. EkoRubber™ consists of skin-friendly cotton. Between the braids air flows freely and skin can breathe. In addition in high compression, these rubber braids provide a gentle massage for skin. Our orthopedic rubber is very friendly for skin.

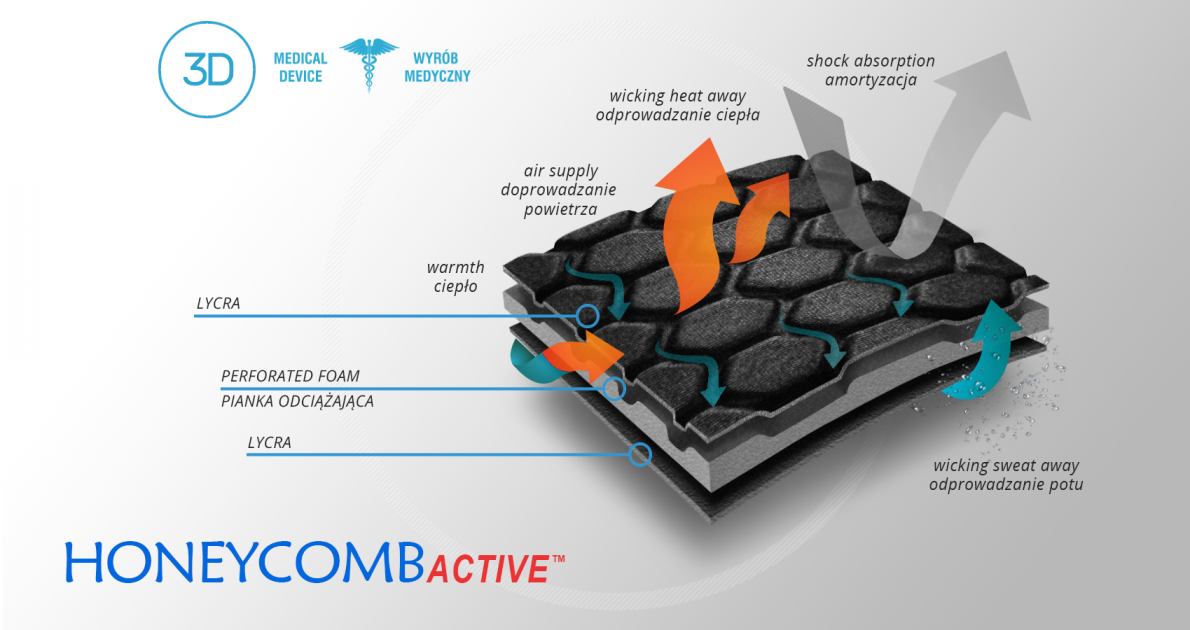

HONEYCOMBactive™ is the thermoformed foam in honeycomb design. It prevents against scratches, abrasions and contusions.

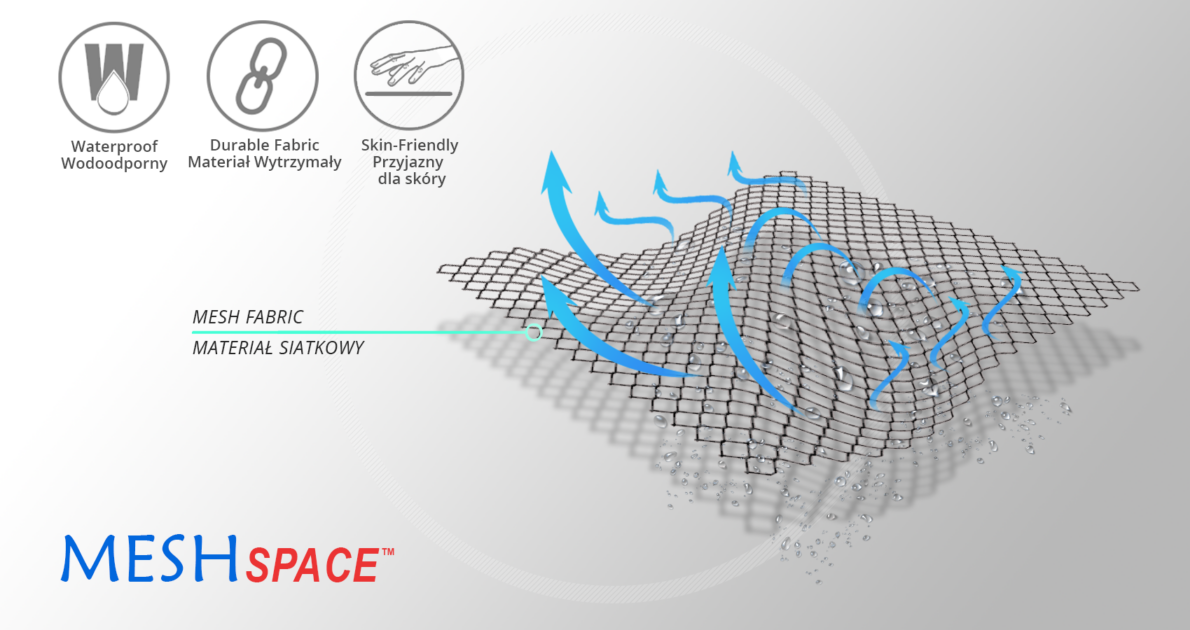

MeshSpace™ is a very strong polyester material that we use in orthopedic products, where high strength of the detail is required, combined with a very small thickness. This raw material is produced by knitting from a very large number of thin, but very strong polyamide yarns. It has an original mesh structure with large openings, which makes it very light, very strong and very airy. An orthopedic device made of this material is neutral for the patient's skin, because no chemicals containing formaldehyde were used during the production of MeshSpace™. In addition, thanks to the fact that the product made of this material has the form of a thin mesh, fresh air successfully reaches the protected limb of the patient and sweat migrates from the skin. The MeshSpace™ material is another example of Reh4Mat's application of the following principle in the production philosophy of its products: Mini Max - minimum product / maximum effect.

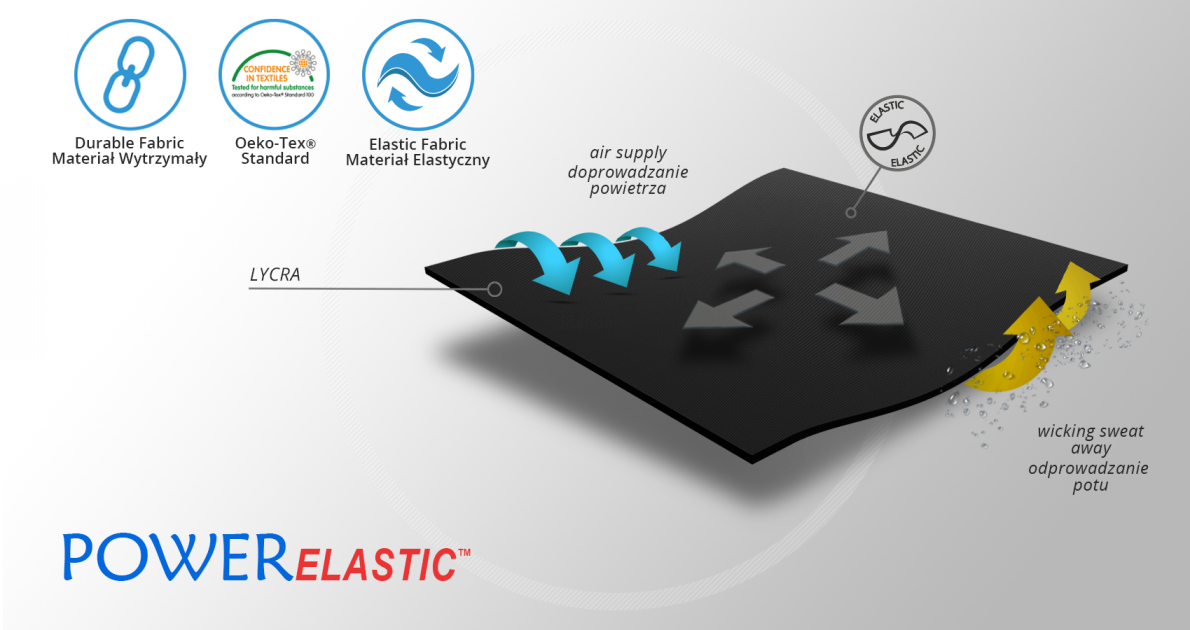

PowerElastic™ is a very thin and very flexible fabric for the production of delicate and sophisticated orthopedic products. It consists of spandex, the action of which is responsible for proper compression and fitting of the product to the patient's body, and reduces muscle vibrations generated during increased physical exertion. It is responsible for maintaining the proper climate next to the skin and effective drainage of sweat, and its structure guarantees velvety softness to the touch. PowerElastic™ is skin-friendly fabric and has the Oeko-Tex Standard 100 certificate.

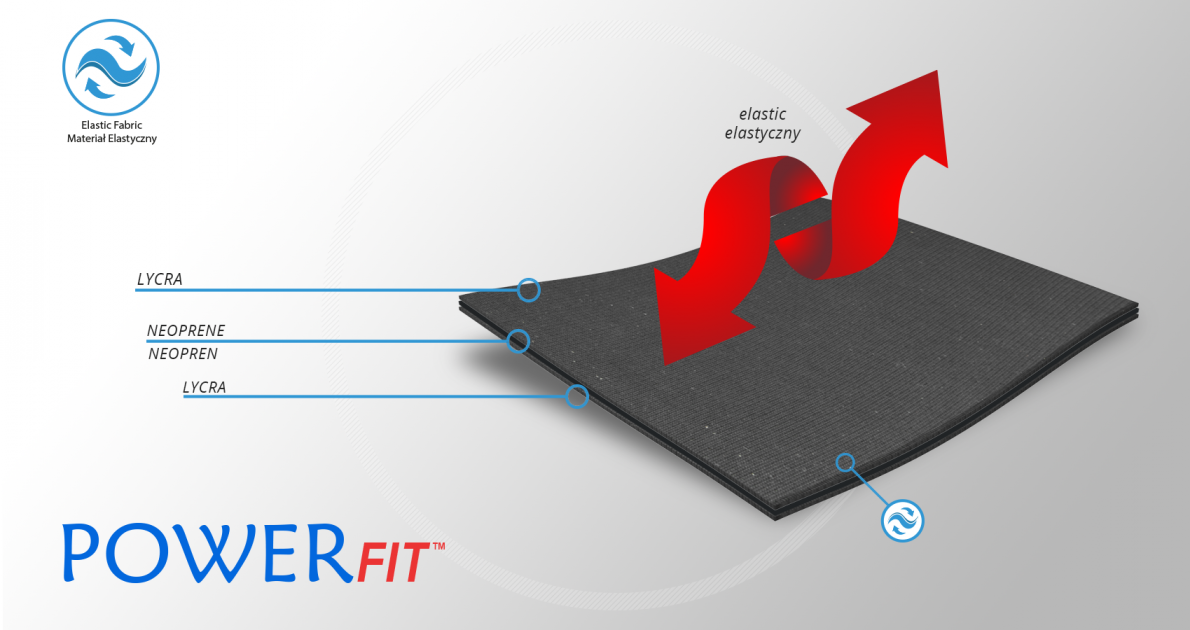

PowerFit™ is a thin, 3-layered lamination, consisted of 2 external spandex layers and internal core. The core aim is to improve compression and absorb shocks in joints and muscles during physical activity. External spandex layers are very resistant to damages and dirt. Braces, made of this fabric, support the body perfectly. Because of their high quality, they can be used even in extreme conditions. PowerFit™ is easy to maintain and can be hand wash, so you can use our braces in fitness exercises and daily trainings. Waterproof material.

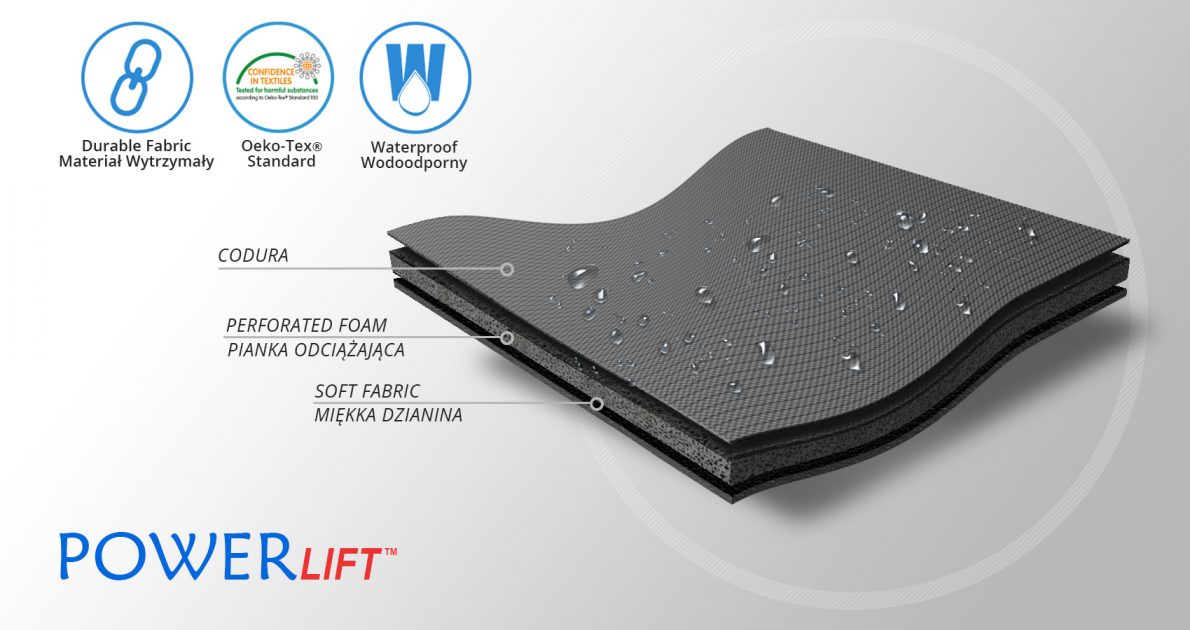

PowerLift™ is an off-loading raw material with a three-layer structure. It consists of a very strong outer fabric, highly abrasion-resistant made of polyamide with a polyurethane coating with Teflon finish, relieving EVA foam and a soft cover knit. Waterproof material.

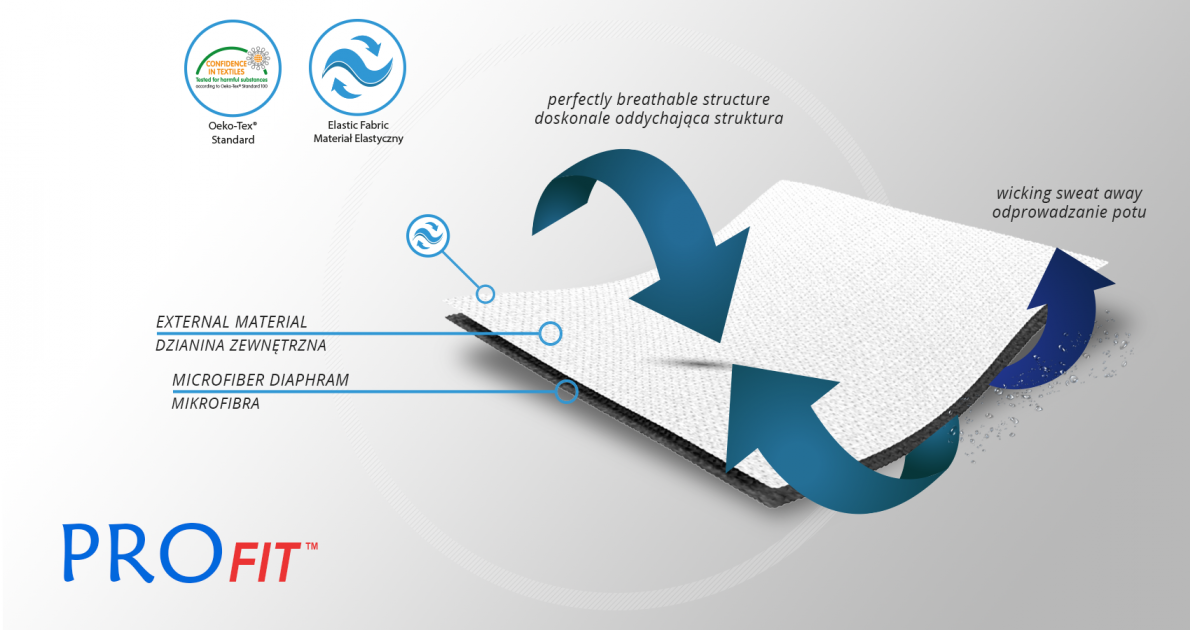

ProFit™ is a double-layer fabric that is elastic in all directions and fits to limb precisely. The external side is made of spandex providing excellent compression and absorbs muscle shocks in physical activity. The internal side consists of microfibre, cotton and elastane what makes it skin-friendly, breathable and provides velvet softness. ProFit™ is friendly and neutral for the skin and has Oeko-Tex Standard 100 certificate. In some products this material can have an internal elastic cotton layer.

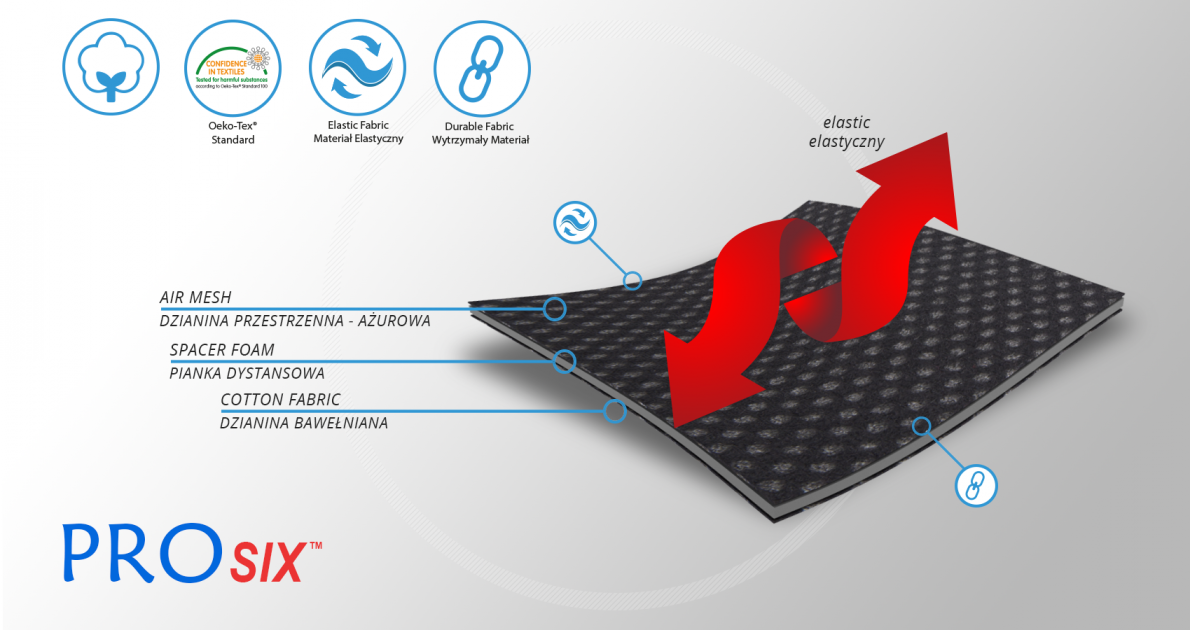

ProSix™ is an innovative fabric 3D, elastic in all directions and fitting to the limb precisely. The external layer is 3D material providing excellent stabilization. There is duothermic spacer foam providing high air permeability and compression inside. The skin has contact with cotton that is breathable and soft. ProSix™ is friendly and neutral for the skin and has Oeko-Tex Standard 100 certificate.

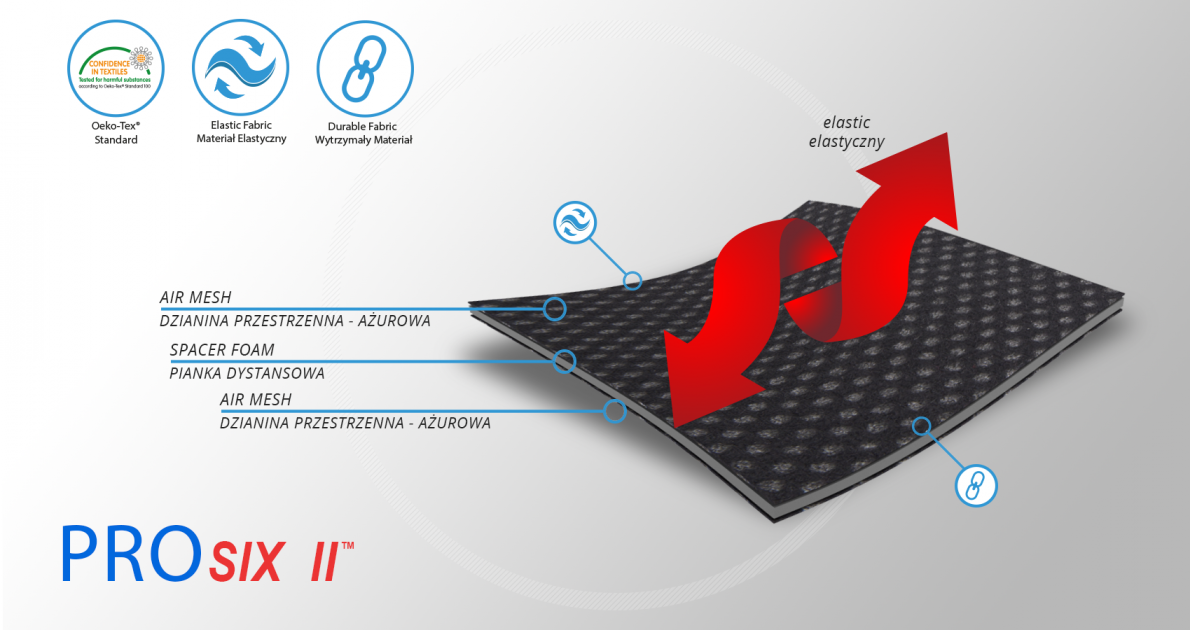

ProSix II™ is an innovative 3D spacer lamination that is elastic in all directions and fits to limb precisely. External layer of ProSix II™ is an elastic 3D fabric providing good stabilization. It guarantees excellent durability so it’s perfect for long-term rehabilitation process. Medial layer of our fabric is duotermic distance foam with high air permeability and minimal water and moisture absorption.

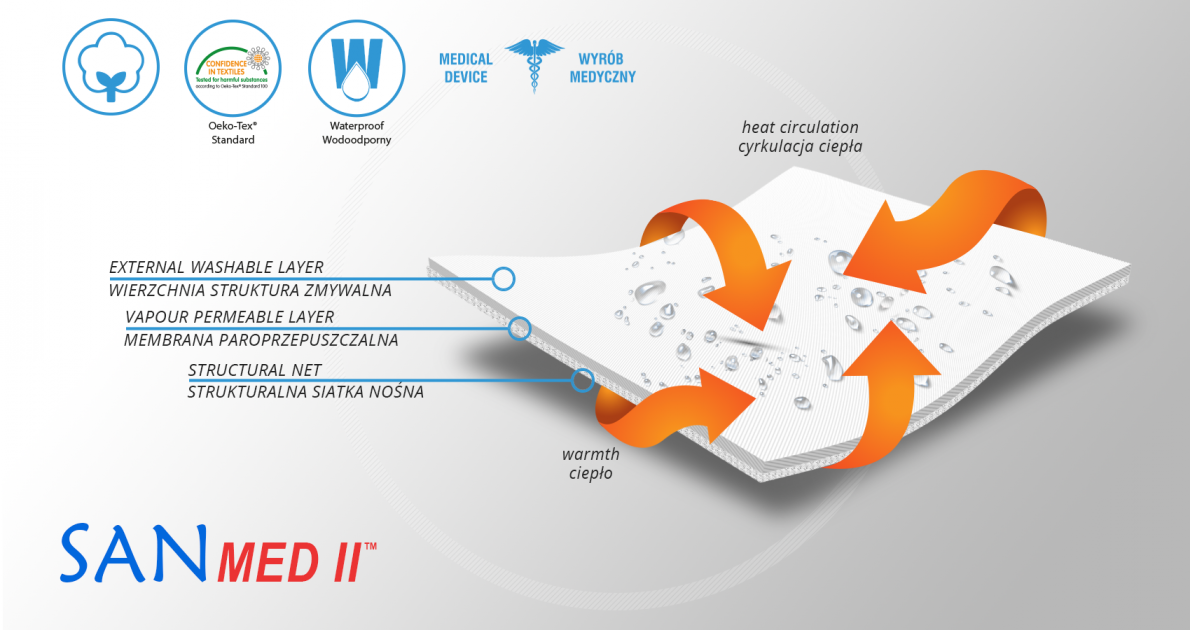

Sanmed II™ is an innovative and very friendly for human skin fabric. It can be sterilized so it can be used by a large number of patients. This material is lightweight and easy to form. What’s the most important, Sanmed II™ can be used in places with a high risk of infections because it consists of antibacterial components based on silver zeolite (AgZ). It provides long-term efficiency and prevents even the most infectious bacteria such as MRSA or E.coli. Sanmed C463 meets the condition according to the Health Minister`s ordinance of 3 November 2004 and Council Directive 93/42/EWG of 14 June 1993. An additional asset of the Sanmed II™ is vapour permeability and water resistance. That’s why it is used as a cover of waterproof anti-bedsore hospital mattresses and couches. In addition, our fabric holds Oeko-Tex Standard 100 certification what proves its chemical neutrality for human skin. Waterproof material.

UniComfort™ is an universal and very comfortable lamination using to produce of lightweight medical devices. This is 2-layered fabric consists of polyamide self-gripping layer and comfort foam. This self-gripping function allows to fit our devices precisely. There is possible to cut away the excess material of UniComfort™ for perfect fitting.

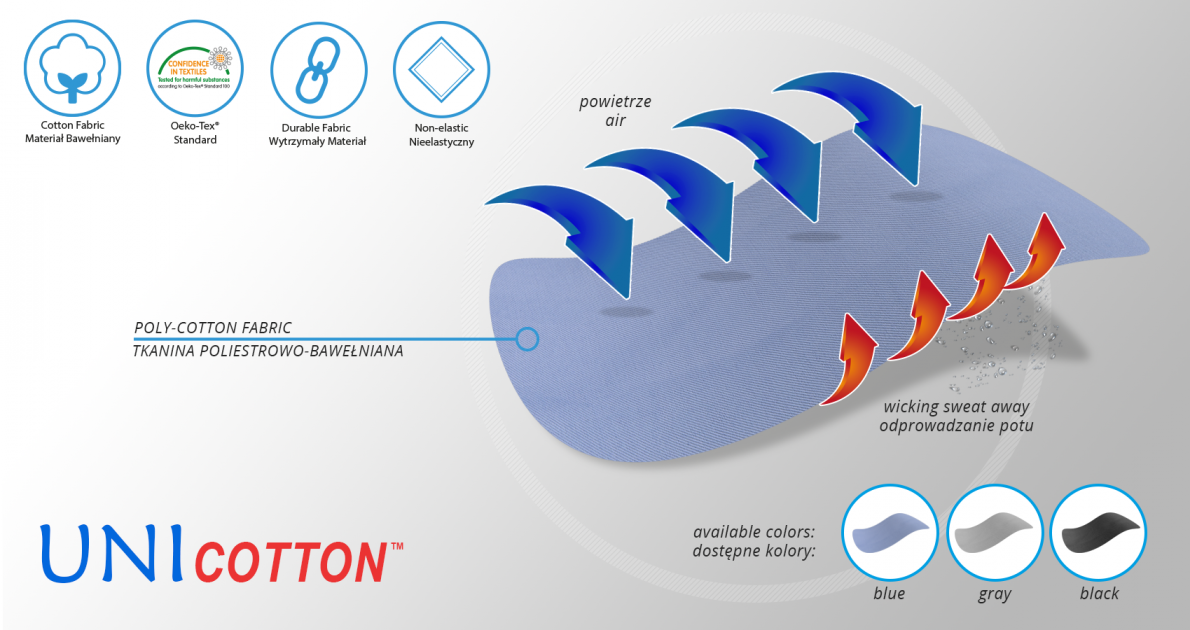

UniCotton™ is a polyester-cotton fabric with versatile use. The fabric is available depending on the needs in different colours and weights, is characterized by high durability and very good performance parameters, it has an Oeko-Tex Standard 100 certificate, which confirms the fact that it is inert to the patient’s skin.

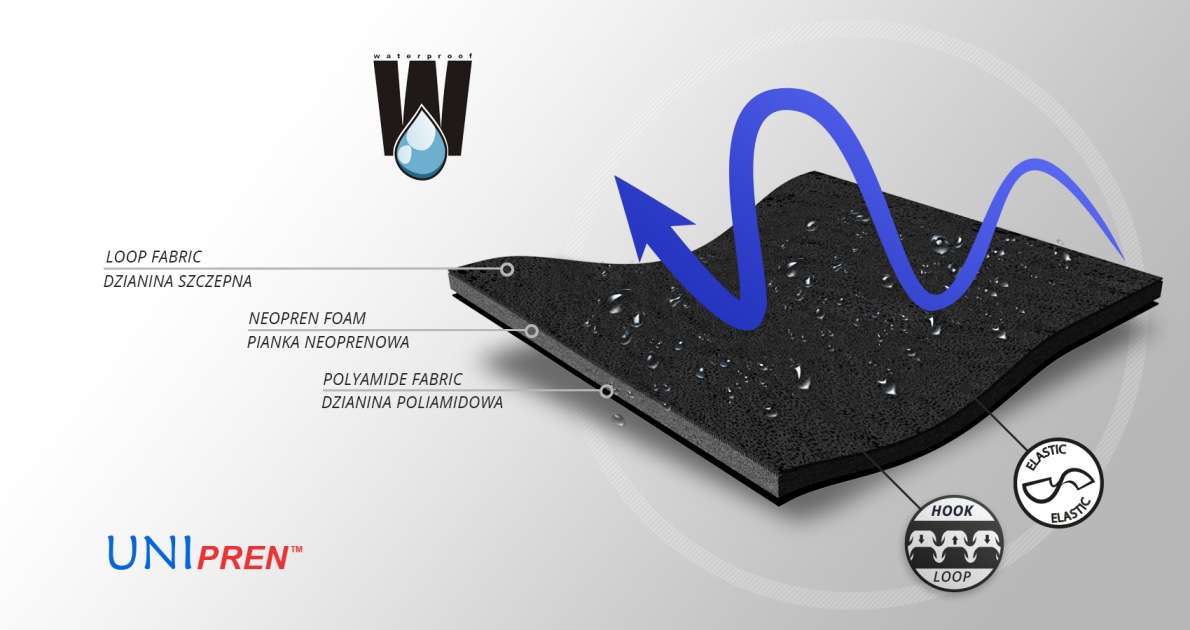

UniPren™ is a universal 3-layer material consisting of an external elastic polyamide cover knit with a self-adhesive function, an internal neoprene foam core and an elastic jersey cover knit. This material is characterized by softness and very high flexibility. A very important advantage of this material is the fact that it is not a knitted product, it does not have thick fibers, so that the weaves of the material do not imprint on the patient's skin and do not cause abrasionsin places of high compression. Products made of UniPren™ are the strongest and most effective stabilizing orthoses available on the market. Self-adhesive function, the raw material makes it much easier to use.

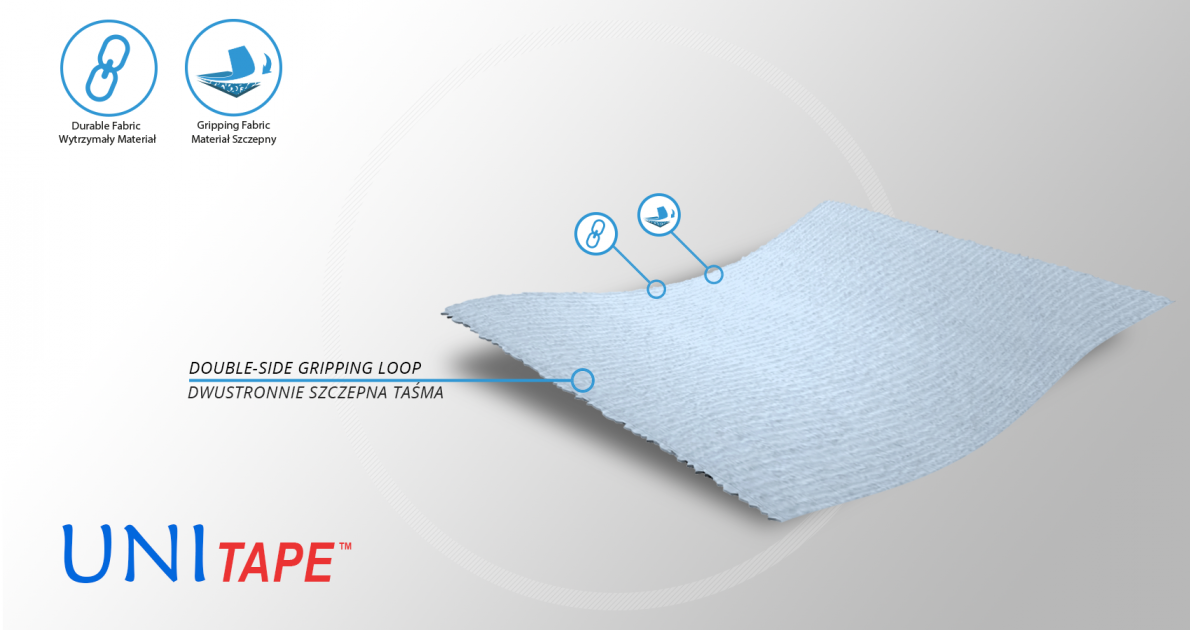

UniTape™ is a technological orthopedic lamination with high durability with double-sided self-gripping function. UniTape™ is very thin and easy to attach what allows to fit the braces precisely.

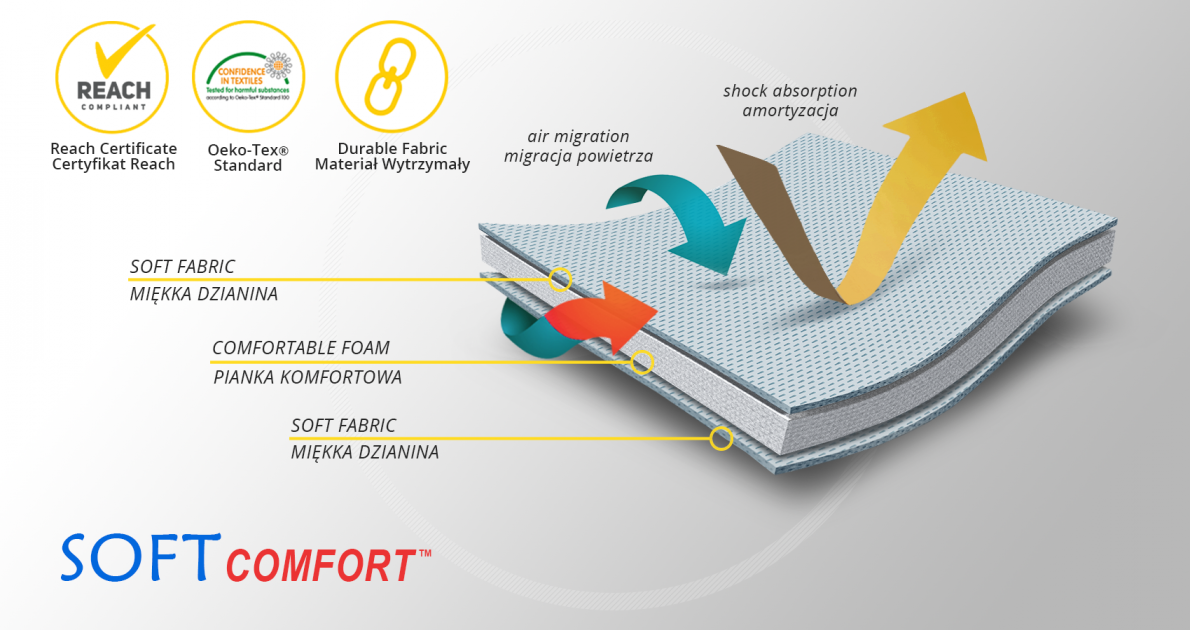

SoftComfort™ - a material specially designed to relieve very delicate places on the patient's body. The cover knit used in the production is made in such a way that it can come into contact with very sensitive skin. This raw material has the Oeko-Tex Standard 100 certificate and complies with the European REACH standard. The structure of the material consists of a very soft comfort foam laminated with a delicate cover knit. The fabric has a perforation that facilitates the flow of air through the material and allows the skin to breathe. The SoftComfort™ material is perfect for the production of linings relieving the rigid and inflexible elements of orthopedic orthoses.

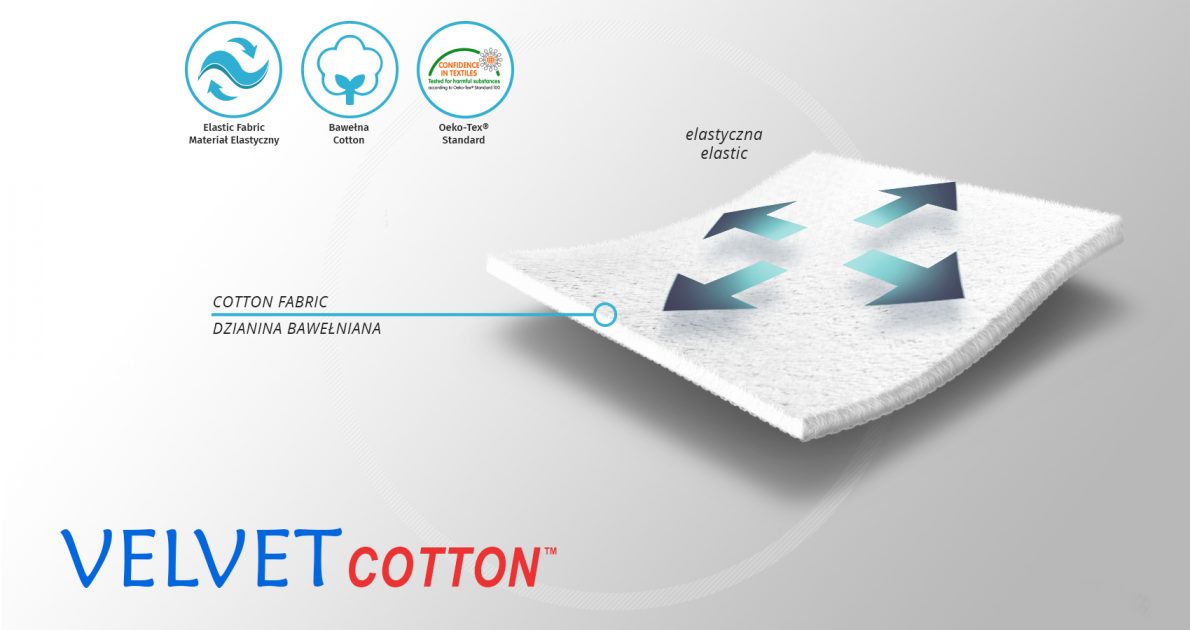

VelvetCotton™ is a skin-friendly material based primarily on pure cotton. The material is the basis for many medical accessories, such as orthopedic pillows, which make them comfortable and completely safe for the patient. VelvetCotton™ is also used in some products from our collection for children, because we are aware that the skin of young patients requires special protection. This knitwear is an excellent alternative to ordinary polyester fabrics available on the market. VelvetCotton™ is characterized by softness, fluffiness and high flexibility, which makes the product highly comfortable to use. The natural composition of the knitted fabric is responsible for maintaining the proper skin climate and for the effective wicking sweat away. VelvetCotton™ has the Oeko-Tex Standard 100 certificate, which confirms its safety for the skin. The material can be cleaned many times without the risk of losing flexibility, and its structure guarantees high durability and resistance.

MICROcomfort™ - everyone knows microfiber very well - the raw material, widely used in recent years, breaks popularity records in many areas. Microfiber is a kind of very thin polyester and polyamide fibers. It is produced with the support of modern technologies that enable obtaining extremely thin synthetic fibers. The low linear density of microfiber makes it soft and delicate, and thanks to the use of synthetic fibers, it does not cause allergies and irritations. Thanks to the micro-holes, it allows for air migration, ensuring full comfort while sleeping. That is why, it can be used both in summer, when the nights are much warmer, and during frosty winter evenings. In addition, microfiber perfectly wicks away moisture and has thermoregulation properties, which significantly affects the comfort of use. Therefore, we decided to use it to manufacture our products. In addition, due to the very elastic fibers, microfiber is an extremely resistant to damages. During washing and ironing, the fabric does not stretch or tear, so buying a microfiber product is an investment for years!